1 - 18

1 Installation

MITSUBISHI CNC

Connection method to a screwless terminal block for fan motor

(1) Lead-out length

Strip the sheath of the cable in the range of 8 to 9mm with an appropriate tool.

Applicable cable size: 0.08mm

2

to 2.5mm

2

(28AWG to 12AWG)

(2) Tool

Use a flat-blade screwdriver whose blade edge size is 0.6×3.5mm for connecting.

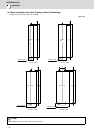

(3) Work procedure

(a) Insert the edge of screwdriver into the insertion point (small square hole) in a diagonal direction. When the

spring touches the blade edge, push the screwdriver down to the position that hits a conductive plate, tilting it

in the inside direction of terminal block. In this state, the spring is completely opened and the screwdriver is

held to the terminal block. Make sure that the screwdriver is completely held, not to create difficulties in

inserting the cable for the next procedure.

(b) Check the stripped length of cable (8 to 9mm) and insert the cable end slowly along the outside of the insertion

point (big square hole) as far as it will go, not to unravel wires. Make sure not to push thin cables too much.

(c) Release the screwdriver while holding one hand against the inserted cable. The spring will be closed and the

cable will be connected.

(d) Gently pull the cable to make sure the connection. No need for a strong pull.

1.2.9 Cable Stress

[1] Do not apply the bending stress and the stress from the cable's own weight on the cable connection part.

[2] Make sure that the cable sheathes will not be cut by sharp cutting chips, worn or stepped on by workers or vehicles.

CAUTION

1. Connection of a cable is restricted to one to one spring.

2. For connecting a cable, both twisted wire and solid wire can be used as it is without termination after the sheath has

been stripped. The cable attached with bar terminal can also be connected.

[1]

[2]

[4]

[3]

Screwdriver

Spring

Conductive plate

Wire