6 - 32

6 Spindle Adjustment

MITSUBISHI CNC

6.1.12 Spindle Motor Temperature Compensation Function

When an IM spindle motor is in a cooled state, its maximum output characteristics tend to degrade compared to when

warmed up.Eventually the spindle acceleration deceleration time may extend or the cutting load on the display may

increase immediately after the start of operation.

This function is designed to reduce the motor output degradation caused by the temperature fluctuation, by applying

control compensation according to the temperature detected by the motor’s built-in thermistor.

For an IPM spindle motor, changes in output characteristics induced by the temperature fluctuation can be ignored in

principle, so no thermal compensation function is provided for this type of motor.

(1) Setting of the temperature compensation gain (SP235)

[1] Set the parameters as SP235(R2H)=150 and SP236(WIH)=0.

* Change SP153(TMLD*) and SP185(TMLDL*) to [original setting x 0.8] respectively and

then turn the NC power OFF and ON.

[2] Rotate the spindle at the command speed of 60r/min.

[3] Make sure that [Cycle counter] on the spindle monitor screen is counting up or down.

[4] Stop the spindle (M5 stop: servo OFF).

[5] Create a program that repeats acceleration/deceleration up to the maximum rotation speed in constant output.

* If the machine’s specified speed is lower than the motor’s maximum speed in constant output,

set the machine specification as the maximum rotation speed.

<Program example for a machining center with the maximum rotation speed in constant output of 7000r/min>

M3 S7000; (Accelerate to the maximum rotation speed)

G4 X2.0; (Dwell for 2.0 seconds)

M5; (Stop)

G4 X2.0; (Dwell for 2.0 seconds)

M99; (Repeat)

[6] Set SP226 bit8 to 1. (Change SP226(SFNC6) from 0000 to 0100.)

[7] Run the program (acceleration/deceleration) which you created in [5].

[8] Make sure that [AFLT gain (dB)] on the spindle monitor is in the range of 90 to 110 during the acceleration/

deceleration operation.

<If [AFLT gain (dB)] is out of the range of 90 to 110>

Adjust SP235(R2H) as follows and run the program created in [5] (acceleration/deceleration).

• When [AFLT gain (dB)] is smaller than 90:

Increment SP235(R2H) by 5 at a time until the gain reaches 90 or higher during the program execution.

• When [AFLT gain (dB)] is 111 or greater:

Decrement SP235(R2H) by 5 at a time until the gain reaches 110 or lower during the program execution.

[9] Stop the spindle when [Temperature (°C)] on the spindle monitor reaches 100 (or the upper limit of

temperature in practical use).

[10] The value of SP235(R2H) you obtain at this time is the result of the final adjustment.

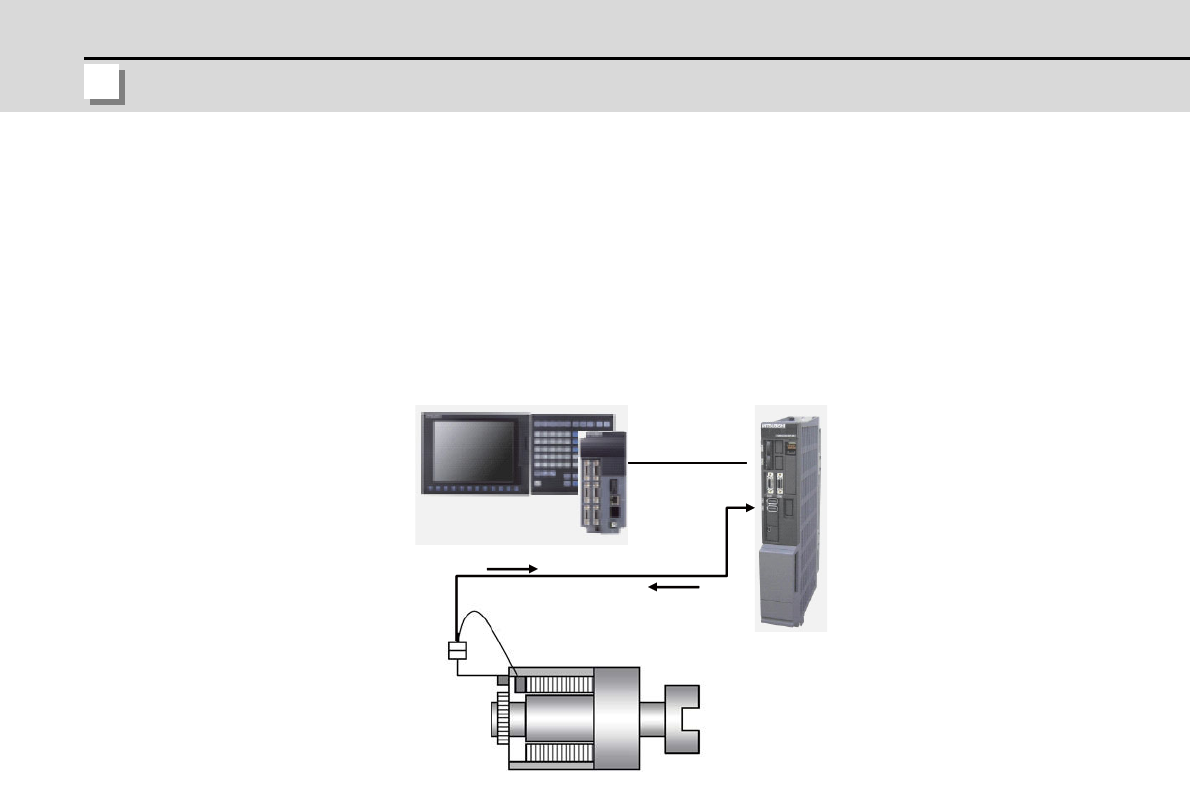

NC

MDS-D2/DH2-SP

Temperature detection

Connect to CN2

Output compensation

Built-in thermistor

(Serial communication)

Motor-end encoder

(Analog signal)

Spindle motor