3 - 7

MDS-D2/DH2 Series Instruction Manual

3.2 Emergency Stop Observation

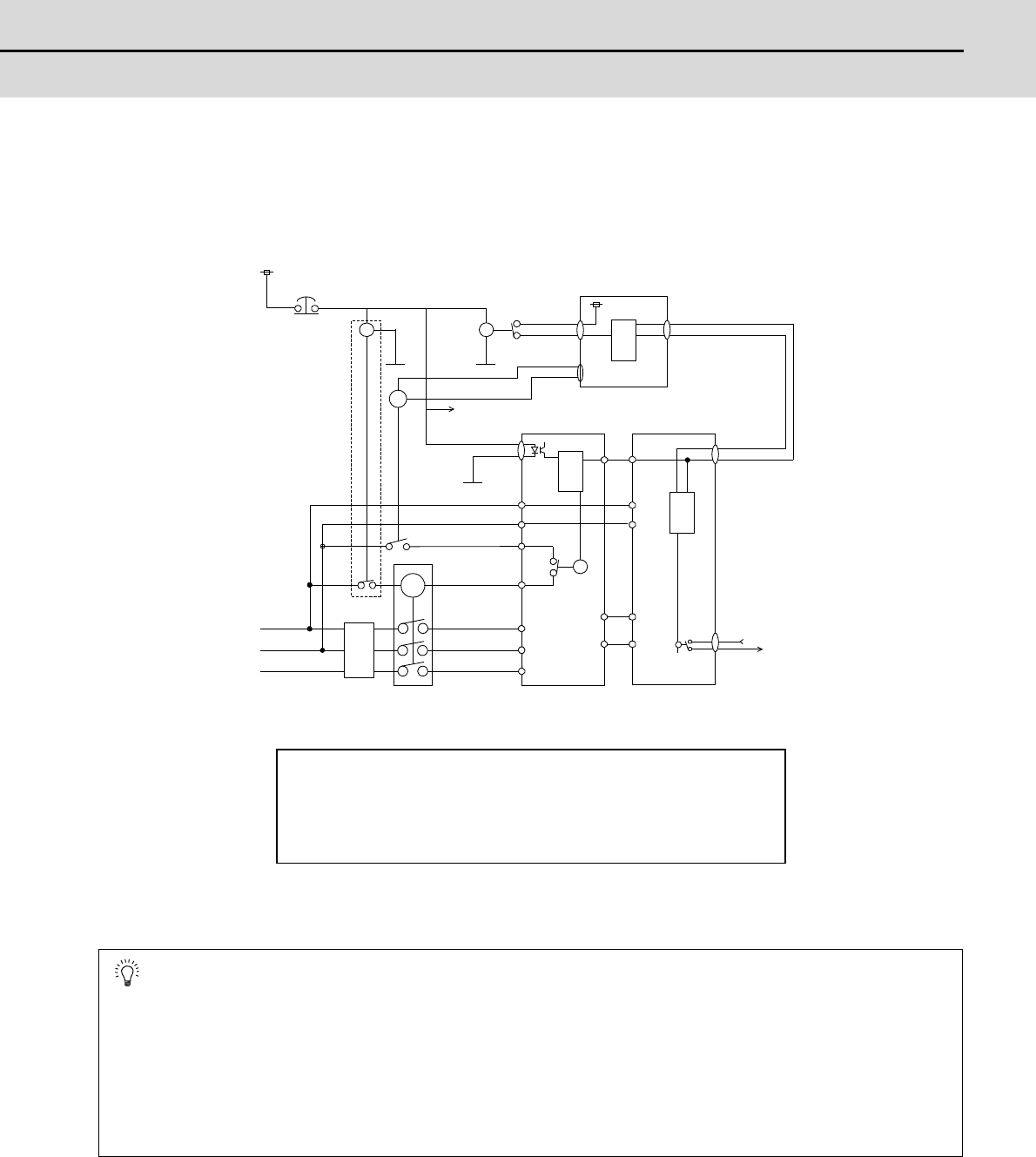

[2] Example of emergency stop circuit

The following diagram shows an example of the emergency stop circuit (EN60204-1 Category 0) in which an

off delay timer (TM1) is installed as a power shutoff method independent from the NC emergency stop input.

The required safety category may be high depending on the machine and the Safety Standards may not be

met. Thus, always pay special attention when selecting the parts and designing the circuit.

Provide a mechanism that shuts off the power even if the CNC system fails.

POINT

Stop Categories in EN60204-1

Category 0: The power is instantly shut off using machine parts.

Category 1: The drive section is stopped with the control (hardware/software or communication network), and then the

power is instantly shut off using machine parts.

(Caution) Refer to the Standards for details.

Refer to Section 9.2.5.4.2 in EN60204-1: Safety of Machinery Electrical Equipment of Machines - Part 1.

TM1

GND

R

RA1

R

GND

EMG

CPU

&

ASIC

SV1/2

CN1A/B

CN24

GND

CPU

&

ASIC

CPU

&

ASIC

MBR*

CN4

CN4

L11

L21

L11

L21

MC1

CN20

MBR*

P

N

L1

L2

L3

MC

MC-OFF*

RA

MC2

R

NC Emergency stop

NC Emergency stop

NC Unit

Servo/Spindle

Drive Unit

Power Supply

Unit

External

Emergency

Switch

Motor

Brake

AC

Reactor

External

Contactor

Setting the off delay timer (TM1) time

Set the TM1 operation time so that it functions after it has been confirmed that

all axes have stopped.

If the set time is too short, a power supply alarm occurs, and the spindle motor

will coast to a stop.

tm ҈ All axes stop time