5 - 18

5 Servo Adjustment

MITSUBISHI CNC

5.3 Characteristics Improvement

5.3.1 Optimal Adjustment of Cycle Time

The following items must be adjusted to adjust the cycle time. Refer to the Instruction Manuals provided with each CNC

for the acceleration/deceleration pattern.

[1] Rapid traverse rate (rapid) : This will affect the maximum speed during positioning.

[2] Clamp speed (clamp) : This will affect the maximum speed during cutting.

[3] Acceleration/deceleration time constant (G0t*, G1t*) : Set the time to reach the feedrate.

[4] In-position width (SV024) : This will affect each block's movement command end time.

[5] Position loop gain (SV003) : This will affect each block's movement command settling time.

(1) Adjusting the rapid traverse

To adjust the rapid traverse, the CNC axis specification parameter rapid traverse rate (rapid) and acceleration/

deceleration time constant (G0t*) are adjusted. The rapid traverse rate is set so that the motor speed matches the

machine specifications in the range below the maximum speed in the motor specifications. For the acceleration/

deceleration time constants, carry out rapid traverse reciprocation operation, and set so that the maximum current

command value at acceleration/deceleration is within the range shown below. The output torque is limited at areas

near the maximum speed, so monitor the current FB waveform during acceleration/deceleration and adjust so that

the torque is within the specified range.

If the drive unit's input voltage is less than the rated voltage, the torque will easily become insufficient, and

excessive errors will occur easily during acceleration/deceleration.

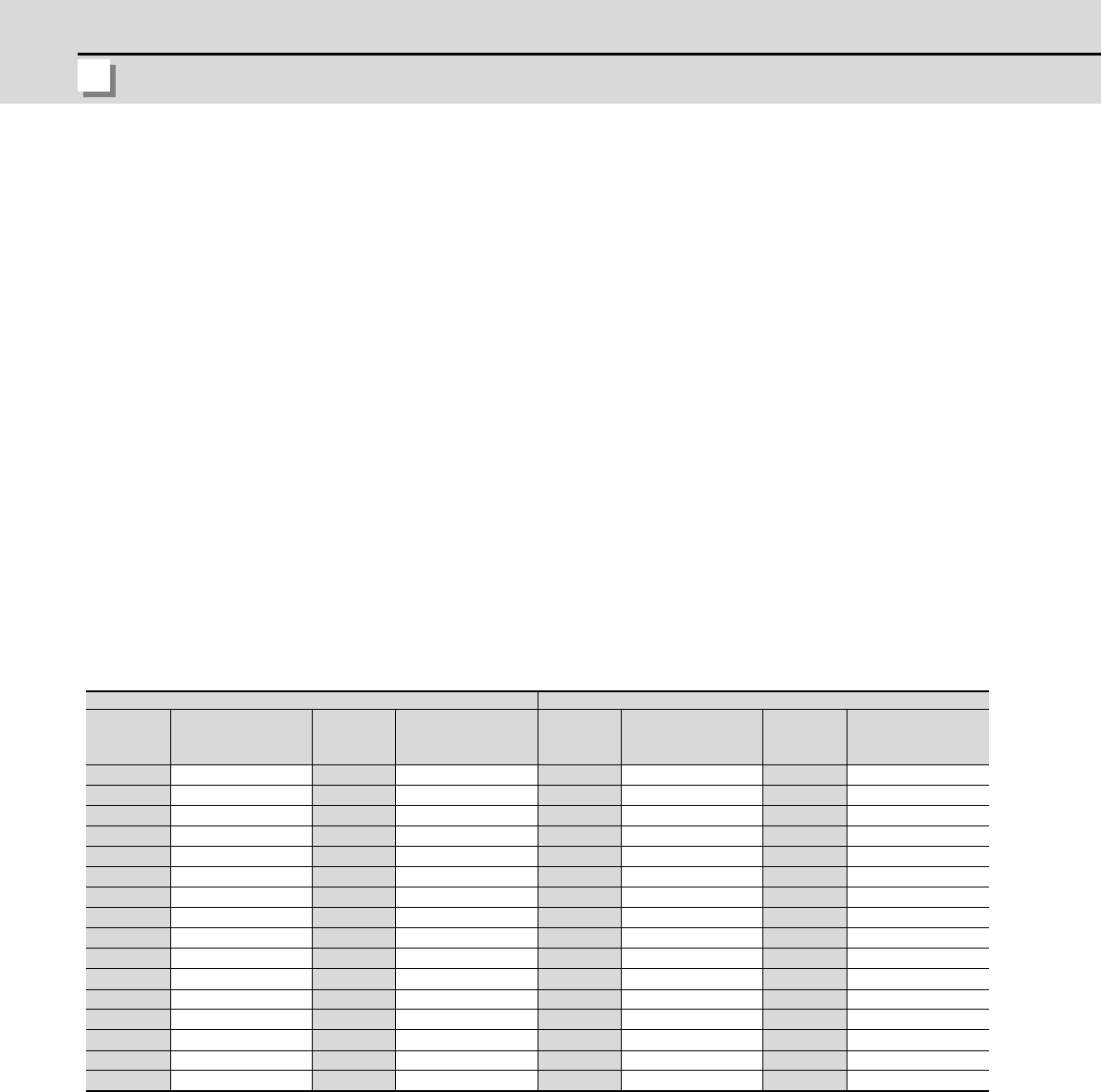

Maximum tolerable current command value when adjusting the rapid traverse acceleration/deceleration time constant

MDS-D2 Series (200V) MDS-DH2 Series (400V)

Motor

model

Max. tolerable

current command

value

Motor

model

Max. tolerable

current command

value

Motor

model

Max. tolerable

current command

value

Motor

model

Max. tolerable

current command

value

HF75 Within 350% HP54 Within 370% HF-H75 Within 350% HP-H54 Within 370%

HF105 Within 270% HP104 Within 300% HF-H105 Within 270% HP-H104 Within 300%

HF54 Within 420% HP154 Within 440% HF-H54 Within 420% HP-H154 Within 440%

HF104 Within 350% HP224 Within 330% HF-H104 Within 350% HP-H224 Within 330%

HF154 Within 380% HP204 Within 300% HF-H154 Within 380% HP-H204 Within 300%

HF224 Within 310% HP354 Within 300% HF-H204 Within 310% HP-H354 Within 300%

HF204 Within 310% HP454 Within 290% HF-H354 Within 330% HP-H454 Within 290%

HF354 Within 420% HP704 Within 220% HF-H453 Within 250% HP-H704 Within 220%

HF123 Within 190% HP903 Within 250% HF-H703 Within 240% HP-H903 Within 250%

HF223 Within 230% HP1103 Within 210% HF-H903 Within 290% HP-H1103 Within 210%

HF303 Within 240%

HF453 Within 300% HF-KP23 Within 250% HC-H1502 Within 170%

HF703 Within 240% HF-KP43 Within 250%

HF903 Within 290% HF-KP73 Within 240%

HF142 Within 190%

HF302 Within 210%