7 - 10

7 Troubleshooting

MITSUBISHI CNC

7.3 Troubleshooting

Follow this section to troubleshoot the alarms that occur during start up or while the machine is operating. If the state is

not improved with the following investigations, the drive unit may be faulty. Exchange the unit with another unit of the

same capacity, and check whether the state is improved.

7.3.1 Troubleshooting at Power ON

If the NC system does not start up correctly and a system error occurs when the NC power is turned ON, the drive unit

may not have been started up properly. Check the LED display on the drive unit, and take measures according to this

section.

The drive unit has started up normally if the following type of emergency stop (E7) is displayed on the display unit's LED

display.

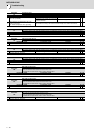

LED

display

Symptom Cause of occurrence Investigation method Remedy

AA

Initial communication with the

CNC was not completed

correctly.

The drive unit axis No. setting is

incorrect.

Is there any other drive unit that has the same

axis No. set?

Set correctly.

The CNC setting is incorrect. Is the No. of CNC controlled axes correct? Set correctly.

Communication with CNC is

incorrect.

Is the connector (CN1A, CN1B) connected? Connect correctly.

Is the cable broken? Replace the cable.

Ab

Initial communication with the

CNC was not carried out.

The axis is not used, the setting is

for use inhibiting.

Is the DIP switch set correctly? Set correctly.

Communication with CNC is

incorrect.

Is the connector (CN1A, CN1B) connected? Connect correctly.

Is the cable broken? Replace the cable.

12

An error was detected in the

unit's memory and IC during the

self-diagnosis at power ON.

The CPU peripheral circuit is

abnormal.

Check the repeatability. Replace the unit.

Check whether there is any abnormality with

the unit's surrounding environment, etc.

Improve the

surrounding

environment.

F1

F+axis No.

E7

Emergency stop

Not lit F2

F+axis No.

E7

Emergency stop

Normal drive unit LED display at NC power ON (for 1st axis)