4 - 78

4 Setup

MITSUBISHI CNC

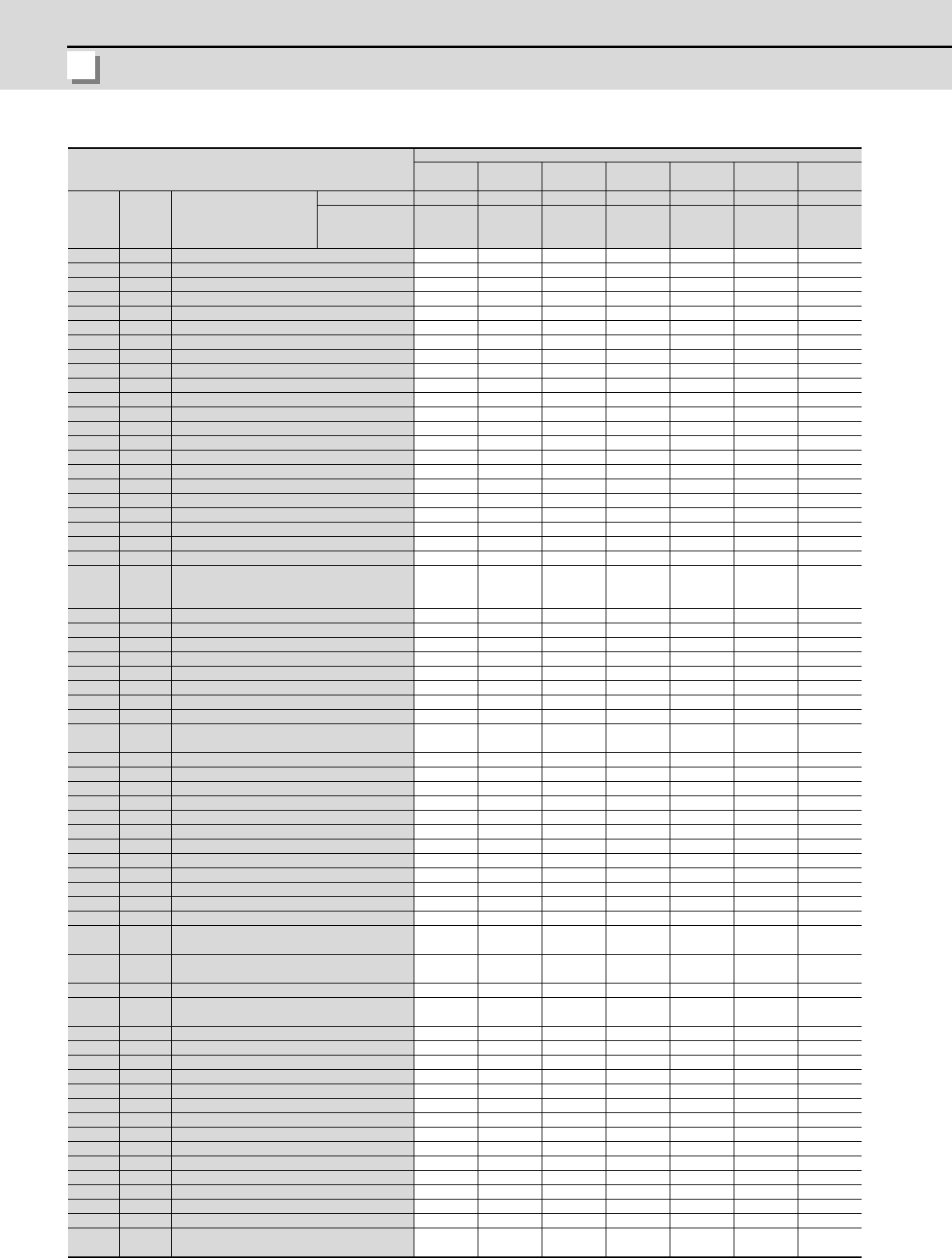

(5) 200V Standard motor SJ-V Series (Standard)

Motor

Parameter

200V Standard motor SJ-V Series (Standard)

SJ-V2.2-

01T

SJ-VL2.2-

02ZT

SJ-V7.5-

03ZT

SJ-V11-

08ZT

SJ-V11-

13ZT

SJ-V15-

01ZT

SJ-V15-

09ZT

No. Abbrev. Details

MDS-D2-SP- 40 40 160 200 200 200 200

MDS-D2-SP2-

4020(L)

4040S

8040(M)

4020(L)

4040S

8040(M)

16080S(L) - - - -

SP001 PGV Position loop gain non-interpolation mode 15 15 15 15 15 15 15

SP002 PGN Position loop gain interpolation mode 33 33 33 33 33 33 33

SP003 PGS Position loop gain spindle synchronization 15 15 15 15 15 15 15

SP004 0000000

SP005 VGN1 Speed loop gain 1 150 150 150 150 150 150 150

SP006 VIA1 Speed loop lead compensation 1 1900 1900 1900 1900 1900 1900 1900

SP007 VIL1 Speed loop delay compensation 1 0000000

SP008 VGN2 Speed loop gain 2 150 150 150 150 150 150 150

SP009 VIA2 Speed loop lead compensation 2 1900 1900 1900 1900 1900 1900 1900

SP010 VIL2 Speed loop delay compensation 2 0000000

SP011 0000000

SP012 0000000

SP013 0000000

SP014 PY1 Minimum excitation rate 1 50 50 50 50 50 50 50

SP015 PY2 Minimum excitation rate 2 100 100 100 100 100 100 100

SP016 DDT Phase alignment deceleration rate 20 20 20 20 20 20 20

SP017 SPEC1 Spindle specification 1 000C 000C 000C 000C 000C 000C 000C

SP018 SPEC2 Spindle specification 2 0000 0000 0000 0000 0000 0000 0000

SP019 RNG1 Sub side encoder resolution 4000 2000 4000 4000 4000 4000 4000

SP020 RNG2 Main side encoder resolution 4000 2000 4000 4000 4000 4000 4000

SP021 OLT Overload detection time constant 60 60 60 60 60 60 60

SP022 OLL Overload detection level 120 120 120 120 120 120 120

SP023 OD1

Excessive error detection width

(interpolation mode - spindle

synchronization)

120 120 120 120 120 120 120

SP024 INP In-position width 875 875 875 875 875 875 875

SP025 INP2 2nd in-position width 875 875 875 875 875 875 875

SP026 TSP Maximum motor speed 10000 15000 12000 8000 10000 8000 8000

SP027 ZSP Motor zero speed 25 25 25 25 25 25 25

SP028 SDTS Speed detection set value 1000 1500 1200 800 1000 800 800

SP029 SDTR Speed detection reset width 30 30 30 30 30 30 30

SP030 SDT2 2nd speed detection setting value 0000000

SP031 MTYP Motor type 2200 2200 2200 2200 2200 2200 2200

SP032 PTYP

Power supply type/ Regenerative resistor

type

0000 0000 0000 0000 0000 0000 0000

SP033 SFNC1 Spindle function 1 0000 0000 0000 0000 0000 0000 0000

SP034 SFNC2 Spindle function 2 0000 0000 0000 0000 0000 0000 0000

SP035 SFNC3 Spindle function 3 1600 1600 1600 1600 1600 1600 1600

SP036 SFNC4 Spindle function 4 0000 0000 0000 0000 0000 0000 0000

SP037 JL Load inertia scale 100 100 100 100 100 100 100

SP038 FHz1 Notch filter frequency 1 0000000

: :::::::

SP046 FHz2 Notch filter frequency 2 0000000

SP047 EC Inductive voltage compensation gain 100 100 100 100 100 100 100

SP048 LMC1 Lost motion compensation 1 0000000

: :::::::

SP052 DFBN Dual feedback control non-sensitive band 0000000

SP053 ODS

Excessive error detection width (non-

interpolation mode)

2000 3000 2400 1600 2000 1600 1600

SP054 ORE

Overrun detection width in closed loop

control

0000000

SP055 EMGx Max. gate off delay time after emergency stop 20000 20000 20000 20000 20000 20000 20000

SP056 EMGt

Deceleration time constant at emergency

stop

300 300 300 300 300 300 300

SP057 GRA1 Spindle side gear ratio 1 1111111

SP058 GRA2 Spindle side gear ratio 2 1111111

SP059 GRA3 Spindle side gear ratio 3 1111111

SP060 GRA4 Spindle side gear ratio 4 1111111

SP061 GRB1 Motor side gear ratio 1 1111111

SP062 GRB2 Motor side gear ratio 2 1111111

SP063 GRB3 Motor side gear ratio 3 1111111

SP064 GRB4 Motor side gear ratio 4 1111111

SP065 TLM1 Torque limit 1 10 10 10 10 10 10 10

SP066 TLM2 Torque limit 2 10 10 10 10 10 10 10

SP067 TLM3 Torque limit 3 10 10 10 10 10 10 10

SP068 TLM4 Torque limit 4 10 10 10 10 10 10 10

SP069 PCMP Phase alignment completion width 875 875 875 875 875 875 875

SP070 KDDT Phase alignment deceleration rate scale 0000000

SP071 DIQM

Variable current limit during deceleration,

lower limit value

50 80 55 70 50 45 60