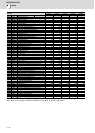

4 - 18

4 Setup

MITSUBISHI CNC

(Note) When driving HF453 with MDS-D2-V2-160160W, set the same parameters.

Motor

Parameter

200V Standard motor HF Series

HF123 HF223 HF303 HF453 HF703 HF903 HF142 HF302

No. Abbrev. Details

MDS-D2-V1/V2- 20 - 40 - 80 160 160W 320 20 - 40 -

MDS-D2-V3- 20 40

L axis

40

MS

axis

40

- - - - 20 40

L axis

40

MS

axis

40

SV001 PC1 Motor side gear ratio ------- ---

SV002 PC2 Machine side gear ratio ------- ---

SV003 PGN1 Position loop gain 1 33 33 33 33 33 33 33 33 33 33

SV004 PGN2 Position loop gain 2 0000000 000

SV005 VGN1 Speed loop gain 1 100 100 100 100 100 100 100 100 100 100

SV006 VGN2 Speed loop gain 2 0000000 000

SV007 VIL Speed loop delay compensation 0000000 000

SV008 VIA Speed loop lead compensation 1364 1364 1364 1364 1364 1364 1364 1364 1364 1364

SV009 IQA Current loop q axis lead compensation 10240 8192 8192 10240 6144 6144 4096 15360 8192 8192

SV010 IDA Current loop d axis lead compensation 10240 8192 8192 10240 6144 6144 4096 15360 8192 8192

SV011 IQG Current loop q axis gain 1536 1280 1280 2048 2048 2048 1536 2048 2048 2048

SV012 IDG Current loop d axis gain 1536 1280 1280 2048 2048 2048 1536 2048 2048 2048

SV013 ILMT Current limit value 800 800 800 800 800 800 800 800 800 800

SV014 ILMTsp Current limit value in special control 800 800 800 800 800 800 800 800 800 800

SV015 FFC Acceleration rate feed forward gain 0000000 000

SV016 LMC1 Lost motion compensation 1 0000000 000

SV017 SPEC1 Servo specification 1 10001400 1000 1000 1000 1000 1000 1000 1000 1400 1000 1000

SV018 PIT Ball screw pitch/Magnetic pole pitch ------- ---

SV019 RNG1 Sub side encoder resolution ------- ---

SV020 RNG2 Main side encoder resolution ------- ---

SV021 OLT Overload detection time constant 60 60 60 60 60 60 60 60 60 60

SV022 OLL Overload detection level 150 150 150 150 150 150 150 150 150 150

SV023 OD1 Excessive error detection width during servo ON 6666666 666

SV024 INP In-position detection width 50 50 50 50 50 50 50 50 50 50

SV025 MTYP Motor/Encoder type 2224 2226 222D 2228 2209 220A 220B 2225 2227 222E

SV026 OD2

Excessive error detection width during servo

OFF

6666666 666

SV027 SSF1 Servo function 1 4000 4000 4000 4000 4000 4000 4000 4000 4000 4000

SV028 0000000 000

: ::::::: :::

SV032 TOF Torque offset 0000000 000

SV033 SSF2 Servo function 2 0000 0000 0000 0000 0000 0000 0000 0000 0000 0000

SV034 SSF3 Servo function 3 0000 0000 0000 0000 0000 0000 0000 0000 0000 0000

SV035 SSF4 Servo function 4 0000 0000 0000 0000 0000 0000 0000 0000 0000 0000

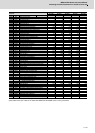

SV036 PTYP Power supply type/ Regenerative resistor type 0000 0000 0000 0000 0000 0000 0000 0000 0000 0000

SV037 JL Load inertia scale 0000000 000

: ::::::: :::

SV046 FHz2 Notch filter frequency 2 0000000 000

SV047 EC Inductive voltage compensation gain 100 100 100 100 100 100 100 100 100 100

SV048 EMGrt Vertical axis drop prevention time 0000000 000

SV049 PGN1sp

Position loop gain 1 in spindle synchronous

control

15 15 15 15 15 15 15 15 15 15

SV050 PGN2sp

Position loop gain 2 in spindle synchronous

control

0000000 000

: ::::::: :::

SV065 TLC Machine end compensation gain 0000000 000

(System parameter area)

SV073 FEEDout Specified speed output speed 0 00000 0 0

(System parameter area)

SV081 SPEC2 Servo specification 2 0200 0200 0200 0200 0200 0200 0200 0200

SV082 SSF5 Servo function 5 0000 0000 0000 0000 0000 0000 0000 0000

SV083 SSF6 Servo function 6 0000 0000 0000 0000 0000 0000 0000 0000

SV084 SSF7 Servo function 7 0000 0000 0000 0000 0000 0000 0000 0000

SV085 LMCk Lost motion compensation 3 spring constant 0 00000 0 0

: : ::::: : :

SV093 0 00000 0 0

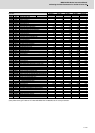

SV094 MPV Magnetic pole position error detection speed 10 10 10 10 10 10 10 10

SV095 ZUPD Vertical axis pull up distance 0 00000 0 0

: : ::::: : :

SV256 0 00000 0 0