68

No.

10

11

12

13

Item

Compressor

stop due to

high pressure

release

Case heater

control

IPDU control

High pressure

prevention

control

Operation explanation and applied data, etc.

Each compressor is stopped should the Pd pressure sensor reach a

value of 3.5 MPa. This control is performed by the header unit and

any follower units.

Heating is provided for both the compressor case and accumulator.

When the compressor in any outdoor unit is stopped, the heater is

switched on to prevent accumulation of refrigerant.

After installation of a system, it should be powered for the specified

period of time prior to operating a test run to prevent damage to the

system.

If the system has not been powered for a prolonged period of time, it

is important to apply power for the specified period of time before

resuming operation.

This function is often performed in conjunction with the compressor

winding heating control. When this occurs, a noise may be heard

which is not an indication of a malfunction.

(1) Contents of control

• The function is performed during when the compressor is off.

• When the TO sensor temp measures 28°C or higher the heater

turns off and turns on when it change:measures 25°C or lower

• The heater remains ‘ON’ for 10 minutes after the compressor

has changed mode from Off to On.

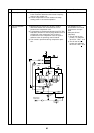

The IPDU controls the inverter compressor by communicating a

command frequency that controls the compressor speed, depending

on any active releases.

The main controls of the IPDU P.C. board are:

(1) Current release control

Feedback from the AC input current sensor (CT) is used to

prevent the inverter input current exceeding its specified limit

(2) Heat sink temperature detection control

• Feedback from the thermistor (TH) on the compressor driving

module is used to prevent the IGBT from overheating. The

highest value is taken from IPDU 1 and IPDU 2 TH sensors.

(3) Over-current protective control

• When an over-current condition is detected by the IPDU, the

compressor is stopped.

(4) Compressor case thermo control

• The compressor stops when the compressor case thermostat is

activated.

• Whenever this condition occurs, a 1 count is added to the

system error count.

• After a period of 2 minutes and 30 seconds, the compressor is

reactivated and the error count cleared if the operation contin-

ues without further error for a period of 10 minutes or more.

• If the error count reaches 4, the check code [H04] is displayed

(for compressor 1) and [H14] (for compressor 2).

(1) High pressure SW control

• The high pressure switch is connected to the IPDU board and is

in the normally closed condition.

• When the high pressure switch is activated, the compressor is

stopped.

• Whenever this condition occurs, a 1 count is added to the

system error count.

• After a period of 2 minutes and 30 seconds, the drive to the

compressor is reactivated and the error count is cleared if the

operation continues with further error for a period of 10 minutes

or more.

• If the error count reaches 4, the check code [P04] is displayed.

Remarks

• A TH sensor is

provided in each two

IPDU.

• The case thermostat

is normally closed

and connected to

interface P.C. board.