204

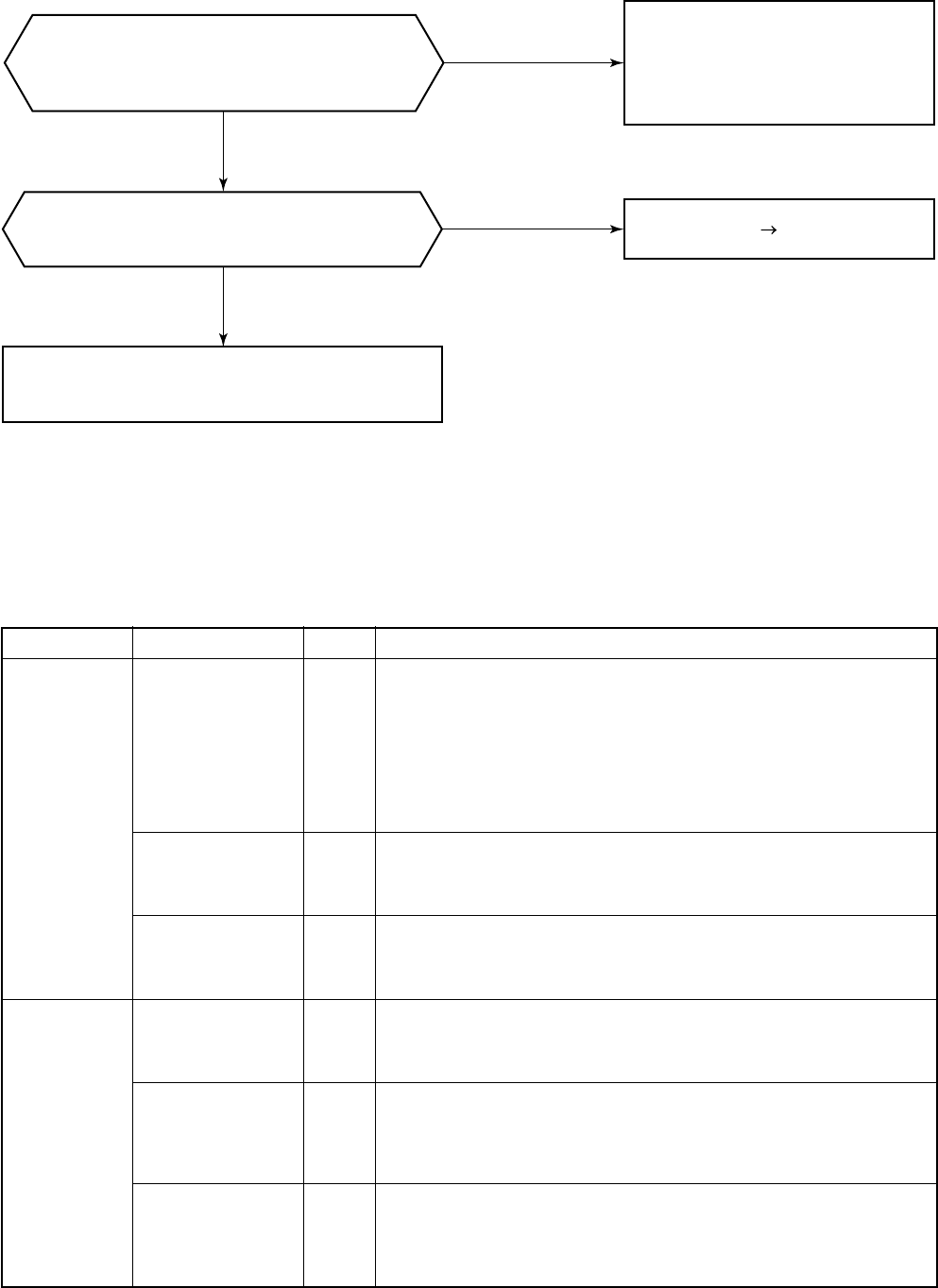

YES

YES

NO

NO

Check oil-equalization circuit in the following procedure

once the compressor is removed.

Correct miscabling or incorrect

installation of the sensors:

TK1: CN514/TK2: CN515

TK3: CN516/TK4: CN523

Sensor error Exchange

Is there any disconnection, mis-cabling,

or incorrect installation of sensors on the unit

of which the compressor has been replaced?

Are the sensor characteristics of

TK1, TK2, TK3 and TK4 sensors correct?

15-3. Procedure to Identify the Cause of Compressor Oil Shortage

Check items and procedure for the oil-equalization circuit under when the compressor has

been removed

Check for

refrigerant

stagnation in

compressor

Check for oil

shortage in

compressor

Check items

Outdoor PMV1, 2, 3

leakage

Check valve leakage

on main discharge pipe

Check valve leakage of

discharge pipe

Check valve leakage of

oil-equalization circuit

SV3A valve leakage

SV3B valve clogging

SV3E valve clogging.

Clogging of oil-return

capillary

SV3D valve capillary

clogging.

Clogging of oil-return

capillary

Position

A

B

C

D

E

F

G

H

I

H

Procedure

1) Pressurize with nitrogen through check joint of liquid pipe and check for

pressure at check joint of discharge pipe.

If pressure of check joint of discharge pipe is high, leakage from outdoor

PMV 1,2, 3 and check valve of main discharge pipe are possible.

Exchange the parts.

2) If the pressure cannot be found, open outdoor PMV 1,2,3 fully and recheck

pressure.

If the pressure from the discharge check joint is high, leakage from check

valve of main discharge pipe is possible. Exchange the parts.

3) If gas leaks from the brazed discharge pipe where compressor has been

removed, when pressurized with nitrogen from the check joint of the main

discharge pipes, the discharge pipe check valves is possibly leaking.

Exchange the parts.

4) If gas leaks from the brazed oil-equalization pipe where compressor has

been removed, when pressurized with nitrogen from the check joint of the

discharge pipe, the check valve of oil-equalization circuit is a possibly

leaking. Exchange the parts.

5) Pressurize with nitrogen with the check joint on the discharge pipe then open

SV3B valve manually.

If gas leaks from the brazed suction pipe where the compressor should be,

there may be a leak in SV3A valve. Exchange the parts.

6) Open SV3E valve manually while pressurizing with nitrogen using the check

joint on the discharge pipe.

If there is no leakage at the brazed suction pipe where the compressor was

removed, the SV3E valve or oil return capillary may be clogged.

Exchange the parts.

7) Open SV3E valve manually while pressurizing with nitrogen from the check

joint of the discharge pipe.

If there is no leakage at the brazed suction pipe where the compressor was

removed, the SV3D valve/capillary or oil return capillary may be clogged.

Exchange the parts.