66

No.

5

6

7

Item

Oil short

protective

control

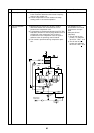

Refrigerant/Oil

recovery control

Defrost control

(Reverse cycle

defrost method)

Operation explanation and applied data, etc.

This control is provided to prevent oil shortage occurring in the

compressors of each outdoor unit.

The control is achieved by ON/OFF operation of the solenoid

valves SV3A, SV3B, SV3C and SV3D.

(1) Oil-short protective control

The oil shortage protection control function stops the outdoor

unit, if an oil shortage continues for 30 minutes, after 2

minutes, 30 seconds the outdoor unit restarts.

If this function is activated on 3 successive occasions, an error

check code (H07) is generated and the outdoor unit is

stopped.

(1) During cooling operation, this function is executed to regularly

to recover the refrigerant/oil from the indoor units and con-

necting pipe-work back to the outdoor unit.

This function is also performed to prevent stagnated refriger-

ant accumulating in the outdoor heat exchanger during low

ambient cooling.

The control is managed by the header outdoor unit.

1) Control conditions

• Cooling oil recovery operation is executed approximately

every 2 hours.

2) Contents of control

• The recovery period lasts for approximately 2 or 3

minutes though this is dependant on the system capacity.

(2) Refrigerant recovery control in heating room

This function is executed regularly to recover the liquid

refrigerant from the indoor unit.

It is also used to recover oil present in the outdoor heat

exchanger during the heating overload operation (except

during defrost operation).

The control is managed by the header outdoor unit.

1) Heating operation oil, recovery control is executed approxi-

mately every hour.

2) The period of recovery lasts for approximately 2 to 10

minutes though this is dependent upon the load condition.

(3) Control for refrigerating / whilst oil recovery in simultaneous

operation.

This function is executed to recover the refrigerating oil

accumulated in the low-pressure gas inter-unit piping.

(regardless of all cooling operation/all heating operation).

1) Control condition

• When the combined time of the compressor-ON has

reached 95 minutes in simultaneous operation.

2) Control contents

When the conditions have been satisfied, upon changing

the indoor unit mode from heating to cooling, (stop the

indoor fan) the oil is recovered for a period between 2

minutes 30 seconds to 10 minutes. The indoor unit in

cooling operation continues operation.

(1) Defrost start condition

The defrost function is initiated when the measurement

temperature taken from the TE sensor is lower than -2°C for a

period of 25 minutes after compressor initial start up and 55

minutes after subsequent start ups.

(2) Contents of control

• If the outdoor units are combined, the minimum duration for

the defrost operation is 2 minutes.

(3) Defrost stop condition

• The outdoor fan speed and compressor inverter frequency

are determined by the measurement of Pd pressure during

defrost operation.

Remarks

• Oil accumulated in the

oil separator is returned

to the compressor.

• Control for refrigerant/

oil recovery is per-

formed approximately

every 2 hours.

• Recovery lasts for

approximately 2 or 3

minutes though this is

dependent upon the

system capacity.

• Heating operation, oil

recovery is executed

approximately every

hour.

• Recovery lasts for

approximately 2 to 10

minutes though this is

dependent upon the

load condition.

• During the defrost

operation, all solenoid

4-way valves are OFF

and all compressors

are operating.