149

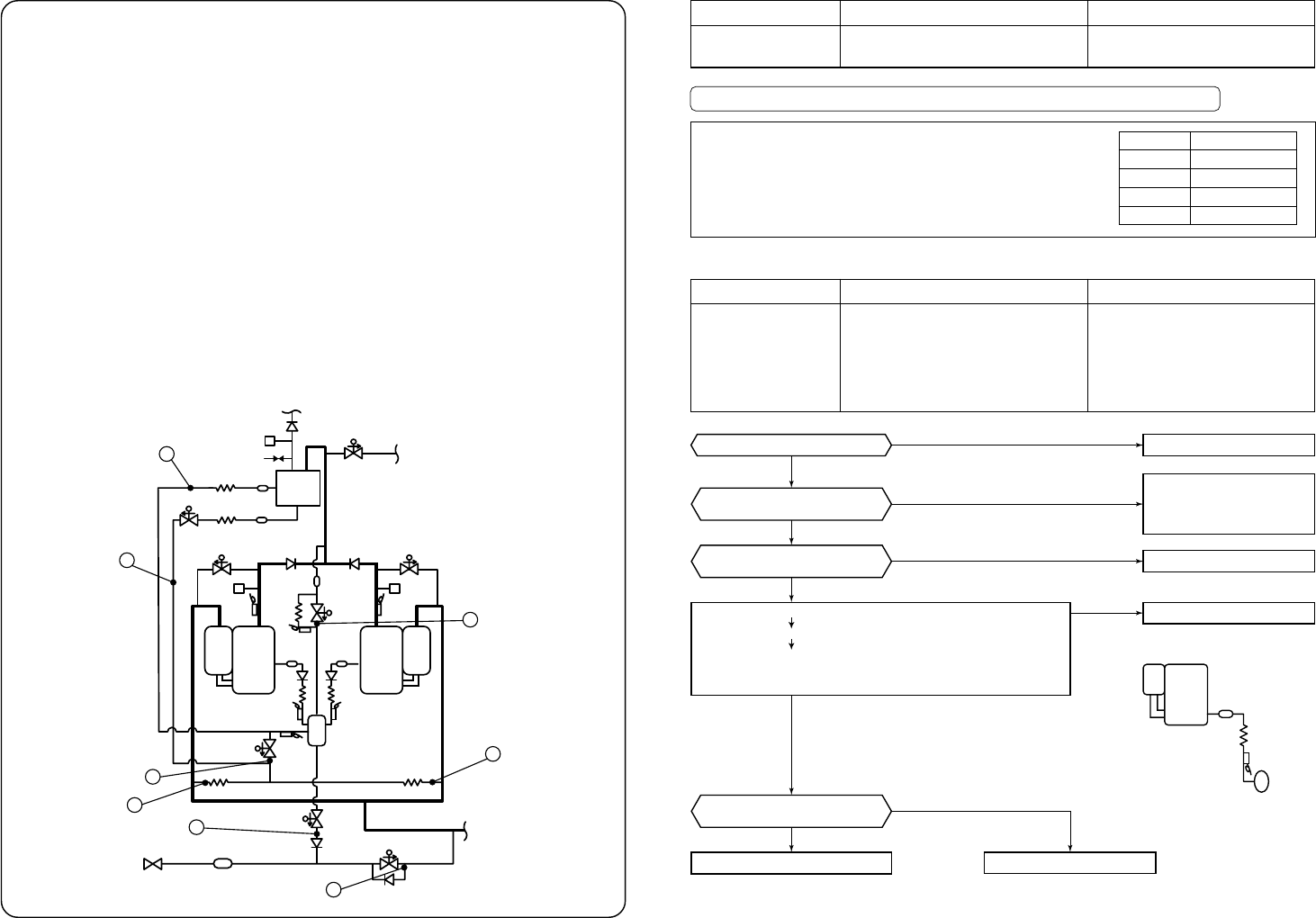

(*3) Check for solenoid valve of outdoor unit (for multiple outdoor unit system)

a) Clogging check for SV3A valve

• While outdoor unit is operating, set up SW01/02/03 = [2] [1] [3] to 7-segment display [Hr], and push SW04

for 2 seconds or more, [Hr] [2] is displayed.

• Set up SW02 = [4], and turn on SV3A valve (7-segment display [Hr] [ 3A]).

• If temperature is low at secondary side of the valve or it does not change, clogging of valve or check valve

is considered (1 in the figure).

b) Clogging check for SV3C valve

• While outdoor unit is operating, set up SW01/02/03 = [2] [1] [3] to 7-segment display [Hr], and push SW04

for 2 seconds or more, [Hr] [2] is displayed.

• Set up SW02 = [6], and turn on SV3C valve (7-segment display [Hr] [ 3C]).

• If temperature does not increase, clogging of valve or strainer is considered (2 in the figure).

(*4)

a) Clogging check for oil-equalization circuit

• Operate the outdoor unit (drive both compressors in the unit).

• After operating for 10 minutes, check temperature of TK1 and TK2 sensors and temperature of oil equal-

ization circuit capillary (7 in the figure) have increased.

(Criteria)

TK1, TK2=Td1, Td2 temperature - Approx. 10 to 30°C

Oil-equalization capillary tubes should be significantly higher than outside air temperature and suction

temperature.

• If temperature is low, a malfunction of capillary, strainer, or check valve is to be considered.

Repair the defective parts.

(SV2)

Solenoid valve

(SV41)

(SV3D)

Check joint

High-pressure

sensor

High-pressure

SW

Oil

separator

Compressor 1

(Inverter)

Strainer Strainer

Sensor

(TK3)

(TK1)

(SV3E)

(TK4)

(TK2)

Solenoid valve

(SV42)

High-pressure

SW

Compressor 2

(Inverter)

Sensor

(TD2)

(TD1)

Oil tank

(SV3A)

Solenoid

valve

(SV3B)

Check

valve

Strainer

5

6

4

7

3

1

7

2

Balance pipe

Packed valve

Check code

[H08] / [d4]

(TCC-L / AI-NET)

Check code name

Oil level detective

temperature sensor error

Cause of operation

TK1 to TK4 sensor Open/Short

Sub-code: 01: TK1 sensor error 02: TK2 sensor error 03: TK3 sensor error 04: TK4 sensor error

Circuit

TK1

TK2

TK3

TK4

Connector

CN514 (Black)

CN515 (Green)

CN516 (Red)

CN523 (Yellow)

This error is an oil level temperature sensor error.

Check for disconnection of the wiring and resistance value of the sensor.

If the sensors are normal, replace the outdoor I/F P.C. board.

Check code

[H16] / [d7]

(TCC-L / AI-NET)

Check code name

TK1 temperature detective circuit error

(Sub-code: 01)

Cause of operation

1. Connection of TK1 sensor. Error in

resistance value of TK1 sensor

2. Oil-equalization circuit error

(Check valve, capillary clogging,

strainer clogging)

3. Refrigerant stagnation in case of

compressor shell

Has TK1 sensor become detached?

Is there incorrect wiring or installation

on TK1/TK2/TK3/TK4 sensors?

Start a test operation in COOL or HEAT mode.

TK1 sensor temp is displayed on 7-segment display with SW01/02/03=[1] [11] [2].

Check TK1 sensor temp. approx. 10 minutes after compressor 1 has operated.

If low temperature continues (approximately outside ambient temp.) or

temperature does not change, a clogging of strainer of oil-equalization circuit,

clogging of capillary tube, or malfunction of check valve is to be considered.

(Note 1) Refer to item [H07] error.

* Outdoor unit temp sensor characteristics-4

* Characteristics-4

Correct wiring/installation.

TK1: CN514

TK2: CN515

TK3: CN516

TK4: CN523

( )

YES

YES

YES

NO

NO

NO

Check I/F P.C. board

Correct installation of sensor.

Are characteristics of TK1 sensor

resistance value normal?

Check the clogging of SV3E valve.

(Note 1)

No error

Error

Error

No error

Sensor error

Replace clogged part.

Replace SV3E valve.

Strainer

Compressor 1

Oil tank

Capillary tube

TK1