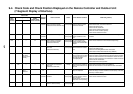

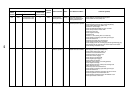

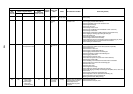

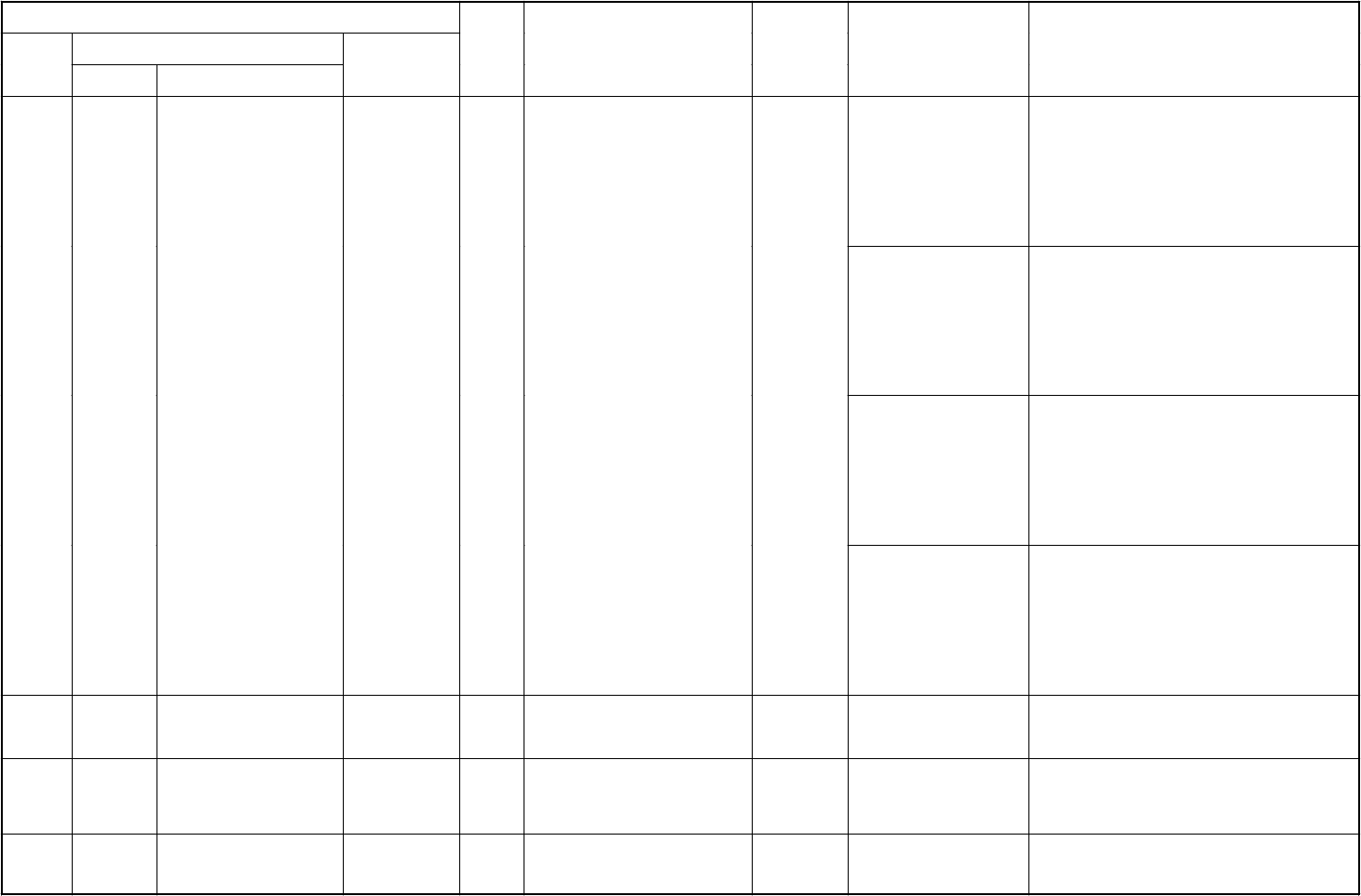

130

Check code

Outdoor 7-segment display

Main

remote

controller

Check code Sub-code

AI-NET

central control

remote controller

Detected

position

Check code name Status Error detection condition Check item (position)

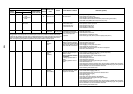

Temperature change of TK1

could not be detected after

compressor 1 started

operation.

• Check TK1 sensor coming-off.

• Check characteristics of TK1 sensor resistance value.

• Check TK1, TK2, TK3, and TK4 misconnection.

• Check operation error of SV3E valve.

• Check capillary clogging of oil-equation circuit and

operation error of stop valve.

• Check refrigerant stagnation in compressor.

• Check MG-SW or OCR.

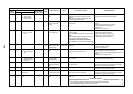

Temperature change of TK2

could not be detected after

compressor 2 started

operation.

• Check TK2 sensor coming-off.

• Check characteristics of TK2 sensor resistance value.

• Check TK1, TK2, TK3, and TK4 misconnection.

• Check SV3E valve operation.

• Check capillar

y

clo

gg

in

g

of oil equalization circuit and

check stop valve operation.

• Check refrigerant stagnation in compressor shell.

• Check MG-SW or OCR.

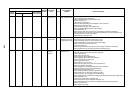

Temperature change of TK3

could not be detected after

compressor started

operation.

• Check TK3 sensor coming-off.

• Check characteristics of TK3 sensor resistance value.

• Check TK1, TK2, TK3, and TK4 misconnection.

• Check SV3E valve operation.

• Check capillar

y

clo

gg

in

g

of oil-equalization circuit and

check valve operation.

• Check refrigerant stagnation in compressor shell.

• Check MG-SW or OCR.

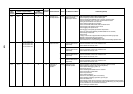

H16 H16

01: TK1 oil circuit system error

02: TK2 oil circuit system error

03: TK3 oil circuit system error

04: TK4 oil circuit system error

d7 I/F

Oil level detective circuit system error

MG-SW error

OCR operation

All stop

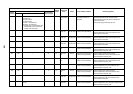

Temperature change of TK4

could not be detected after

compressor started

operation, or the difference

from other TK sensor

changed for a constant time

only within the specified

range.

• Check TK4 sensor coming-off.

• Check characteristics of TK4 sensor resistance value.

• Check TK1, TK2, TK3, and TK4 misconnection.

• Check SV3E valve operation.

• Check capillar

y

clo

gg

in

g

of oil-equalization circuit and

check valve operation.

• Check refrigerant stagnation in compressor shell.

• Check MG-SW or OCR.

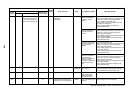

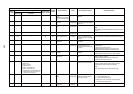

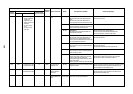

L03 —— 96 Indoor Duplicated indoor center units Correspondin

g

unit only stops.

There are multiple header

units in a group.

• Check indoor address.

• Check the change of remote controller connection

(Group/individual) after indoor address setup.

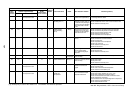

L04 L04 — 96 I/F Duplicated outdoor line address All stop

Line address setup is

duplicated against the

outdoor unit in different

refrigerant pipe system.

• Check line address.

L05 —— 96 I/F

Duplicated indoor units with priority

(Displayed on indoor unit with priority)

All stop

Indoor units with priorit

y

were

duplicated.

• Check display of indoor unit with priority.

MG-SW : Magnet Switch, OCR : Over-current Relay