Technical Product Manual - DCT1900

Maintenance, Fault Finding Procedures

Maint-DCT1900/R8/mw 6-1

© 2000-2005

CHAPTER 6

Fault Finding Procedures

6.1 Introduction

These fault finding procedures are designed to help maintenance personnel locate and eliminate

faults in the shortest possible time. The fault finding extends to the level of a replaceable part

(DTU, SPU, power supply unit, etc.). Although cabling and connection errors are not covered,

suggestions will be given to check these items when the fault is presumed to be introduced by

them. The basic assumptions for the fault finding are:

z Only one fault at a time.

z The fault is persistent (not intermittent).

z Fault is not due to cabling or bad connections.

The execution of the following steps will avoid unnecessary fault finding:

z Analysis of the fault symptoms.

z Visual inspection of the system (cabling, connections, power cords).

If these steps do not solve the fault, the flowcharts given in Paragraph 6.4 can be used.

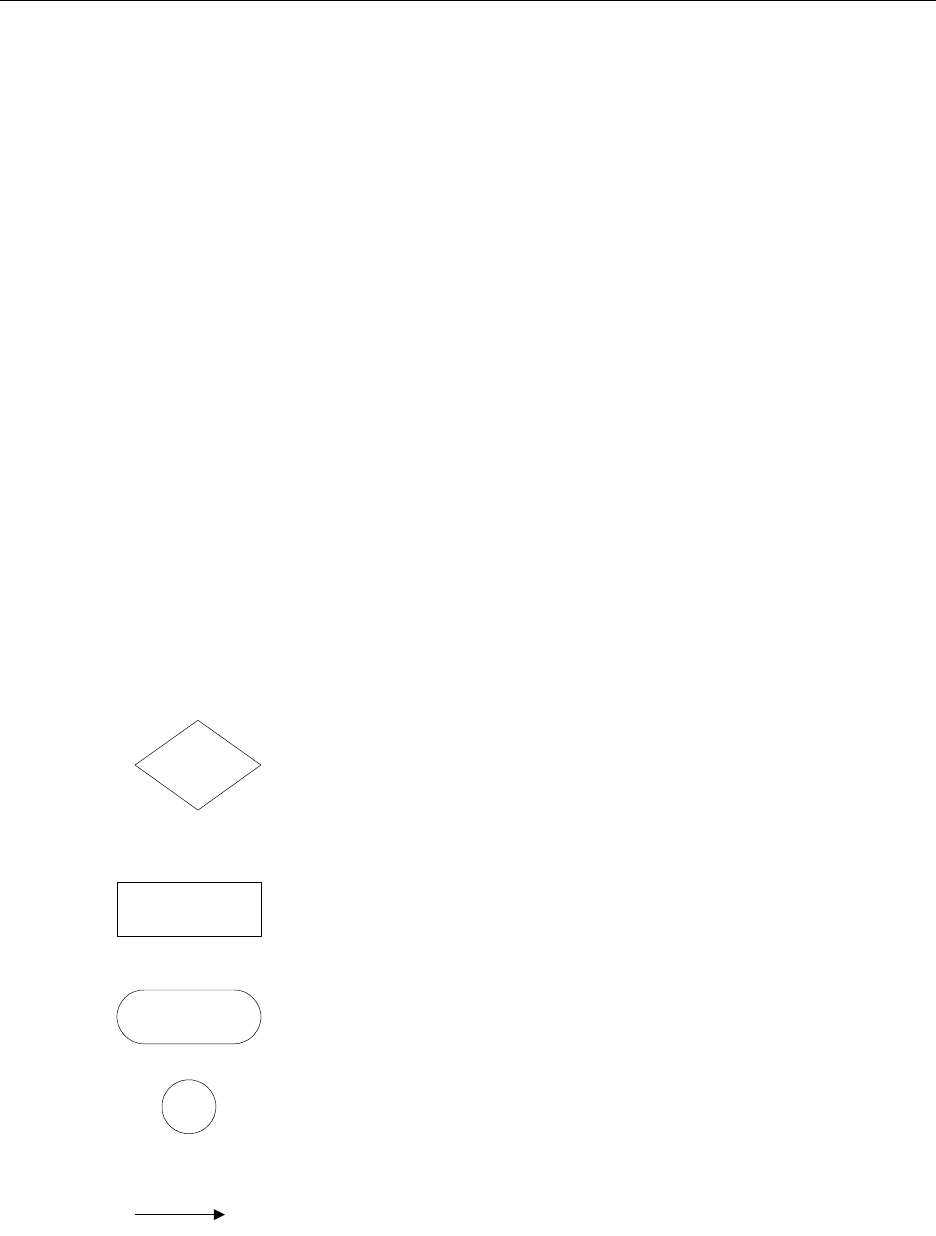

6.2 Symbols used in the Flow Charts

Question

Instruction

References

Flow

Question?

1

2

3

4

This symbol contains a question with two or three possible

answers being "Yes", "No", or other Text.

Inputs are points 1 or 4 and outputs are points 2 or 3 or 4.

This symbol contains an instruction for the maintenance

engineer.

This symbol is used as a starting point for a procedure (e.g.

START), as a reference to another flowchart, or to end a

procedure (END).

This symbol is used as a reference within one flowchart. This

can be to a part of the flowchart on another page (e.g. A or B)

or to a part of the flowchart on the same page (e.g. 1).

Arrows indicate the normal flow.