3. INSTALLATION

BAS-300G, BAS-311G, BAS-326G

11

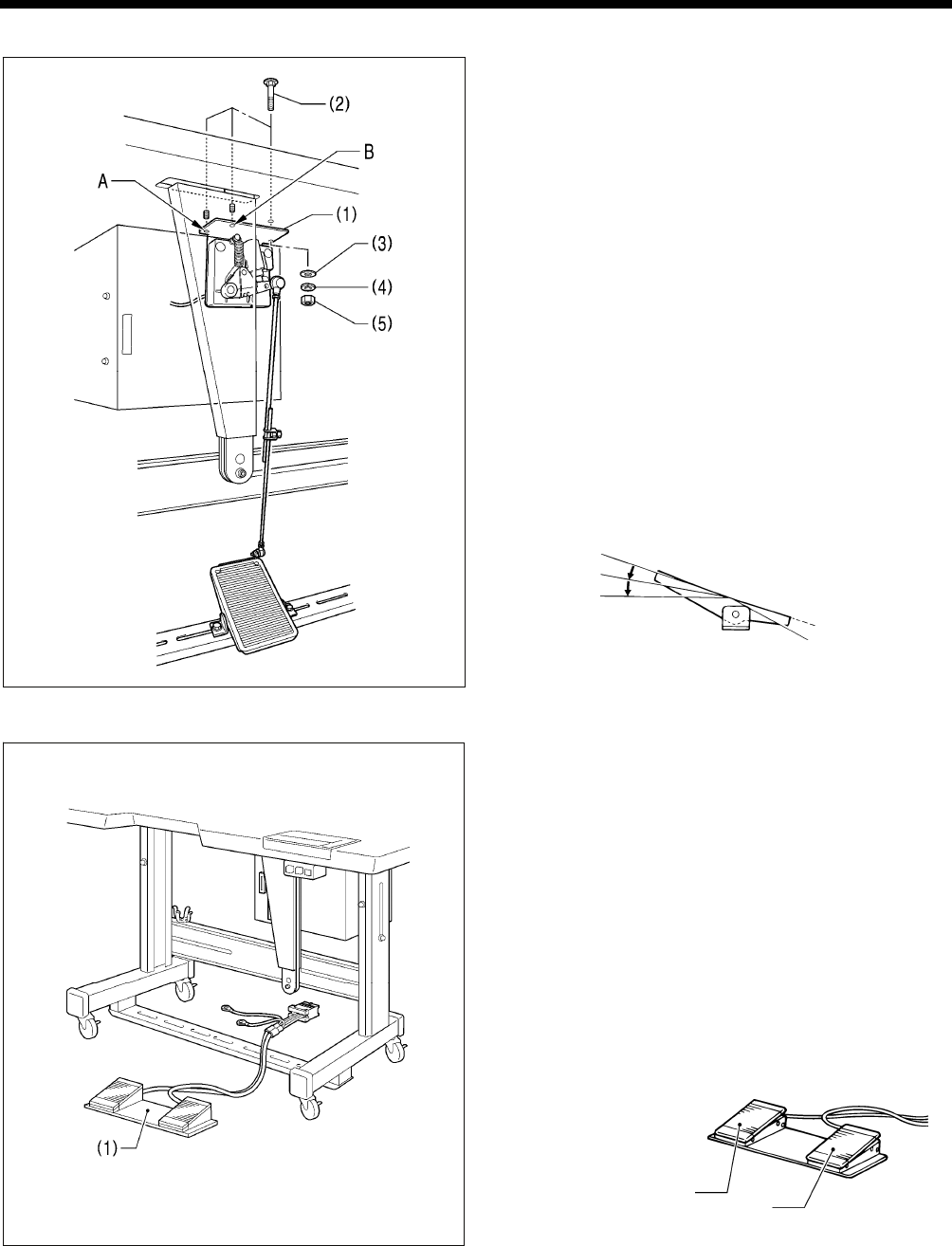

3-7. Installing the treadle unit (motor-driven work clamp specifications)

(1) Treadle unit

(2) Bolts [3 pcs.]

(3) Plain washers [3 pcs.]

(4) Spring washers [3 pcs.]

(5) Nuts [3 pcs.]

NOTE:

• Install the bolt for mounting hole A before installing the oil

pan. (Refer to “3-3. Installing the oil pan.”)

• Mounting hole B is used to install the gas spring supports

with the bolt, plain washer, spring washer and nut. (Refer

to "3-4. Installing the machine head".)

* Use a commercially-available foot switch and connecting rod.

* If changing the mounting position for the treadle unit, use the

accessory bolts, plain washers, spring washers and nuts.

<Foot switch operating method>

When the foot switch is depressed to the 1st step, the work

clamp is lowered, and when it is depressed to the 2nd step, the

sewing machine starts sewing.

3-8. Installing the two-pedal foot switch (pneumatic work clamp specifications)

(1) Foot switch

Insert the connector for the foot switch (1) into P6 (FOOT) on

the main PCB. (Refer to "3-9. Connecting the cords".)

* Be sure to make the ground connection. (Refer to “3-10.

Connecting the ground wire”.)

<Foot switch operating method>

When the work clamp switch (left) is depressed, both work

clamps are lowered, and when the start switch (right) is

depressed, the sewing machine starts sewing.

* The work clamp lowering method can be changed using

memory switch No. 002. (Refer to “6-3. List of memory

switch settings” in the instruction manual CD.)

4921Q

1st step

2nd step

4441Q

4923Q

Start switch

Work clamp switch (2-step)

2972B