A part’s listing in this catalog does not guarantee its availability.

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. Rev.1 10/08

Page 110 of 124

DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS

Standardization of Proven Concept

Using the experience gained in designing and producing

special Dynafl ex couplings, LORD has developed a new

standard product line of heavy-duty Dynafl ex couplings.

These couplings have a specially designed elastomeric

element bonded to a metal inner member which is then

preloaded and friction-fi t into an outer member.

This unique concept provides low torsional spring rates

which effectively isolate critical vibratory disturbances in

driveline and accessory systems, thus prolonging equip-

ment life. Misalignment and torsional shock loads are

absorbed by shear defl ection in the elastomeric element.

The ability of the coupling to slip at the outer member

with short duration shock overloads protects the drive-

line and accessory components from premature failure.

The Dynafl ex LCD Series Coupling has been particularly

successful for diesel driven applications.

Dynafl ex LCD Series Couplings are available in 75 to

2000 hp ratings at a nominal 2000 rpm. Each size is also

available in two stiffness values. These are referred to

as the A and C stiffness values. The C stiffness parts are

normally stocked.

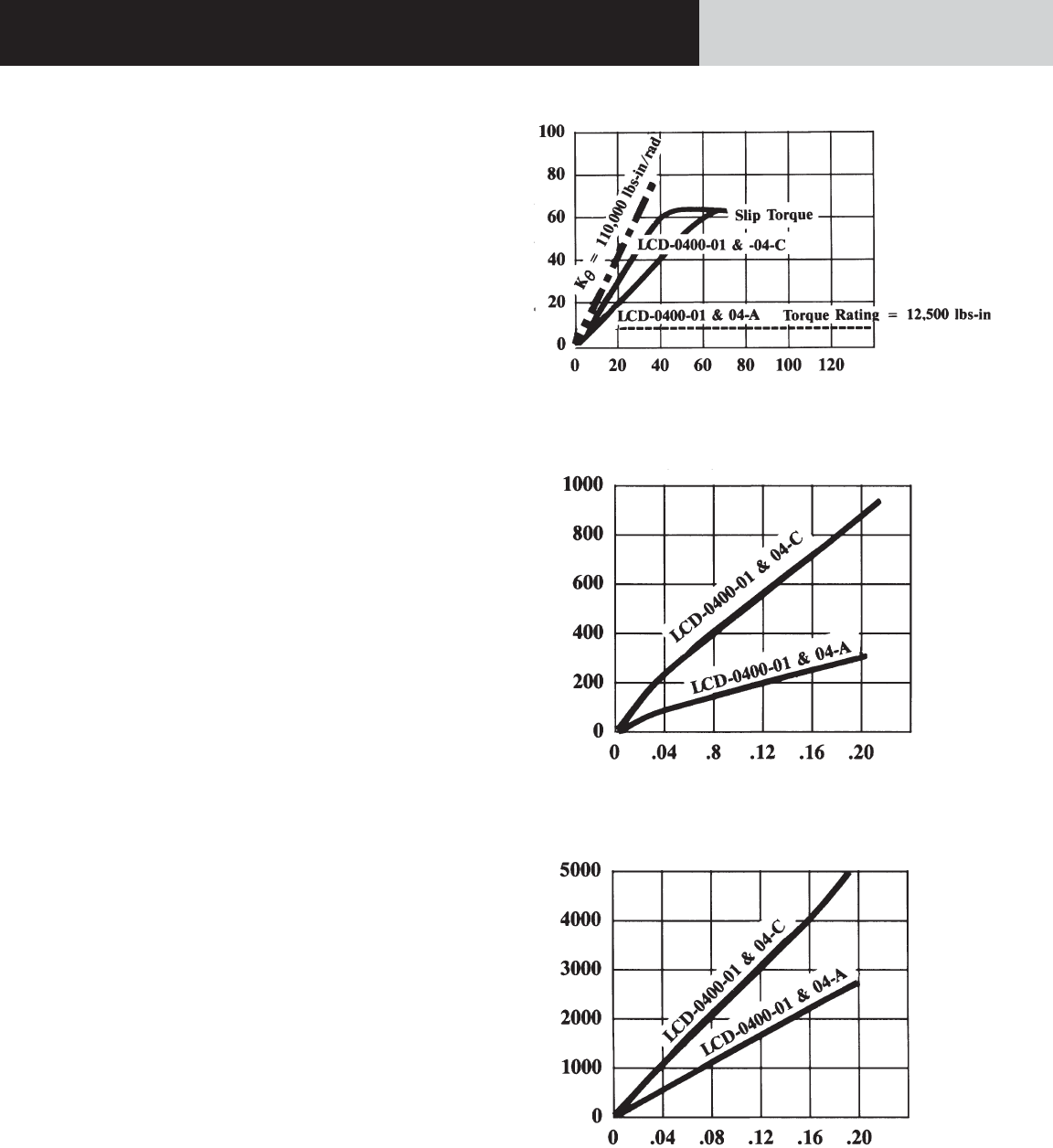

Load Defl ection Data

Figures 1 through 3 illustrate the torque or load versus

defl ection characteristics for the -A and -C stiffnesses of

the LCD-0400 size couplings. The general characteristics

of these curves are typical for all Dynafl ex LCD Series

Couplings.

Figure 1 shows the linearity of the coupling spring rate

at (and well above) the rated capacity of 12,500 lb-in

torque. The curves also demonstrate the unique overload

slip characteristic at about 60,000 lb-in torque. It should

be noted, however, that the overload protection results

from slipping of the coupling. This slipping generates

heat, and therefore continuous running at overload could

be injurious to the coupling.

Figures 2 and 3 illustrate the fl exibility of Dynafl ex LCD

Series Couplings to accommodate axial and radial

misalignment. The -A variation is made in a softer elas-

tomer to produce a lower torsional spring rate and there-

fore had the lower axial and radial spring rates. All spring

rates are ideally linear over the normal operating range of

defl ection.

Figure 1 – Torsional Load/Defl ection Curves

Figure 2 – Axial Load Defl ection Curves

Figure 3 – Radial Load Defl ection Curves

Defl ection (in)

Load (lb)

Angular Defl ection (deg)

Torque Load (lb-in) x 000

Defl ection (in)

Load (lb)