A part’s listing in this catalog does not guarantee its availability.

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. Rev.1 10/08

Page 109 of 124

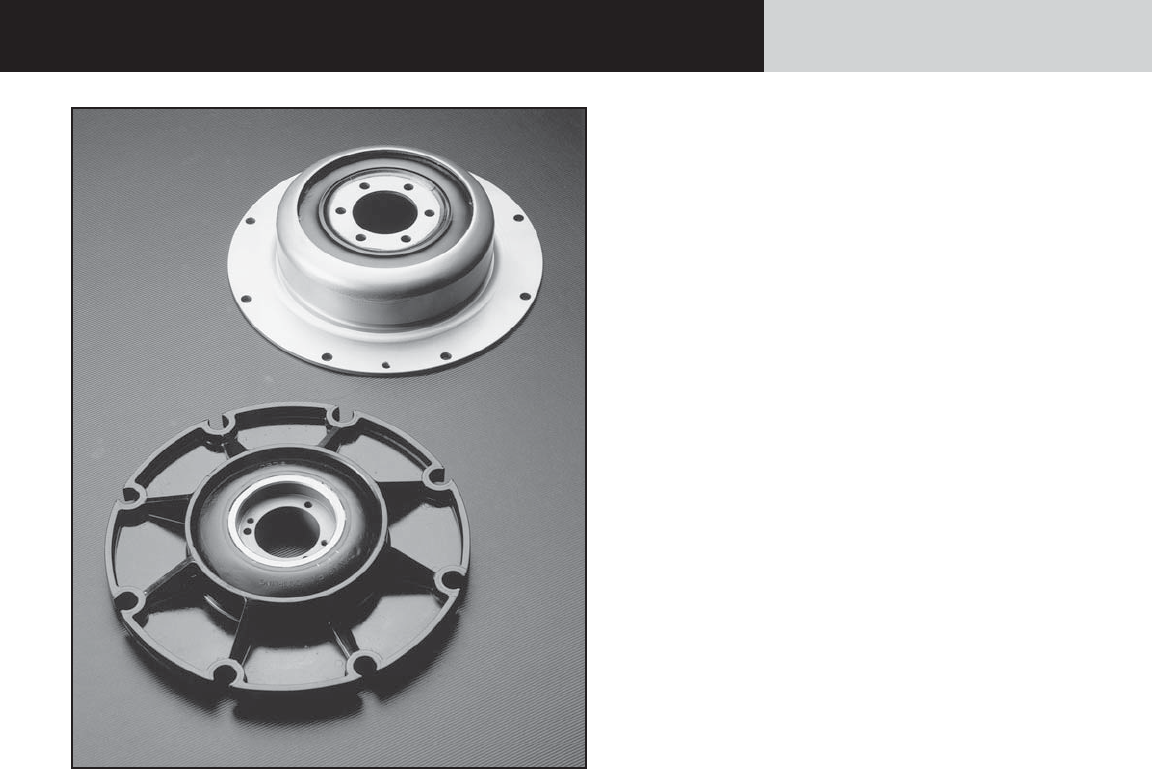

DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS

Dynafl ex

®

LCD Series Couplings

Rated: 75 to 2000 hp at 2000 rpm

LORD Dynafl ex LCD Series Couplings have been

developed to overcome numerous torsional problems

associated with vehicular and industrial driveline

systems. These couplings increase equipment life

by protecting against torsional vibration, shock and

misalignment.

Typical application attachments include:

• Flywheel to shaft

• Flywheel to hub (splined)

• Shaft to shaft

• Floating shaft

Features and Benefi ts

• Protection from torsional shock loads

• Design fl exibility

• Safe for occasional severe overloads

• Vibration isolation – extremely low torsional spring

rate is achieved with the Dynafl ex LCD Series

Coupling, using elastomer in shear. This allows for low

system natural frequencies and isolation of fi rst mode

driveline disturbances.

• Damping at resonance – the elastomer used in

Dynafl ex LCD Series Couplings effectively reduces

vibration at resonance.

• Shock protection – torsional shock loads are attenu-

ated by large shear defl ection of the elastomer. In

the case of severe overloads, equipment damage is

prevented by slippage between the elastomer and

the outer housing.

• Misalignment accommodation – elastomer fl exibility

allows for angular, parallel and axial misalignment.

• Long service life – Dynafl ex LCD Series Couplings

have proven themselves under demanding and

rugged service conditions.

• Maintenance-free – elastomer fl exibility accommo-

dates all motion without wear, eliminates the need for

lubrication.

• Noise reduction – no metal-to-metal contact; elas-

tomer attenuates structure-borne noise and isolates

vibration from components that would act as noise

generators.

• Attachment – fi ts many standard SAE fl ywheels.

• Design fl exibility – standard rubber molds are used

to produce each different size coupling shown in

this catalog. Often it is necessary to change metal

components for custom applications. This is common.

• Systems Engineering – LORD has in-house computer

capabilities for multi-mass torsional analysis to assist

in proper coupling selection.