A part’s listing in this catalog does not guarantee its availability.

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. Rev.1 10/08

Page 91 of 124

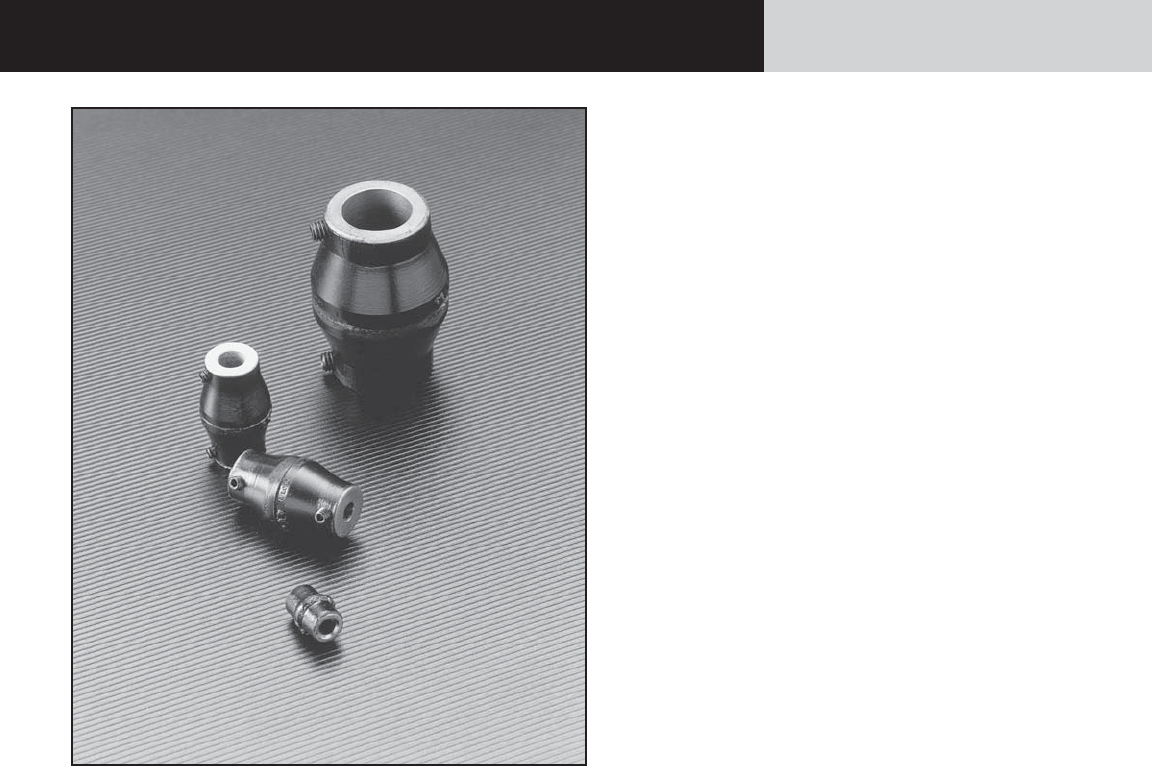

DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS

Dynafl ex

®

Shear-Type Couplings

Rated: 1/50 to 1 hp at 1750 rpm

LORD Dynafl ex Shear-Type Couplings are compact,

one-piece fl exible couplings economically constructed to

isolate low-frequency vibration and accommodate multi-

directional misalignment.

These couplings reduce the adverse effects of transient

shock torques, torsional vibration, noise and misalign-

ment associated with small equipment drivelines. This

results in longer service life, smoother, quieter operation,

less maintenance, and lower cost for your end product.

Shear-Type fl exible couplings are useful in many small

equipment driveline applications. Multi-directional

misalignment capabilities make them ideally suited for

fractional horsepower drivelines demanding noise reduc-

tion, vibration isolation and maintenance-free operation.

Typical applications include:

• Information Systems – Motor drive, printer rollers,

indexing devices, linear actuator, drives and card

sorters

• Hospital Bed – Actuator drive

• Dynamometer – Driveline

• Tachometer – Driveline

• Pumps, Blowers, Compressors – Driveline

Features and Benefi ts

• High torsional defl ection

• Easy installation

• Versatile application potential - fractional horsepower

couplings are available in a range of sizes to permit

matching a specifi c coupling to your application.

• One-piece construction – convenient for small

equipment with fractional horsepower requirements.

Specifi ed torque rating allows 15° angular defl ection

for excellent vibration isolation.

• Multi-directional misalignment accommodation – elas-

tomeric fl exibility accommodates misalignments up to

1/32 inch parallel, 2° angular.

• Vibration isolation – low torsional stiffness is achieved

with the shear-type fl exible coupling because

the rubber is loaded in shear. This allows for low

system natural frequencies and excellent driveline

disturbances.

• Shock protection – torsional shock loads are attenu-

ated by torsional defl ection of the elastomer. Torsional

fl exibility smooths out rotational disturbances and

protects system components from early fatigue

failure.

• Noise reduction – no metal-to-metal contact; elasto-

meric barrier reduces gear noise, transmission and

motor hum between shifts.

• Maintenance-free – elastomer fl exibility accommo-

dates all motion without metal-to-metal wear, elimi-

nates the need for lubrication.

• Long service life – Dynafl ex Shear-Type Couplings

have proven themselves under demanding service

conditions. Elastomers resist effects of abrasive mate-

rials, oil and grease.

• Attachment – shear-type fl exible couplings are avail-

able in an assortment of bore sizes. Refer to Table 1.

• Constant velocity – inherent design properties

produce a rotational constant velocity.