A part’s listing in this catalog does not guarantee its availability.

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. Rev.1 10/08

Page 114 of 124

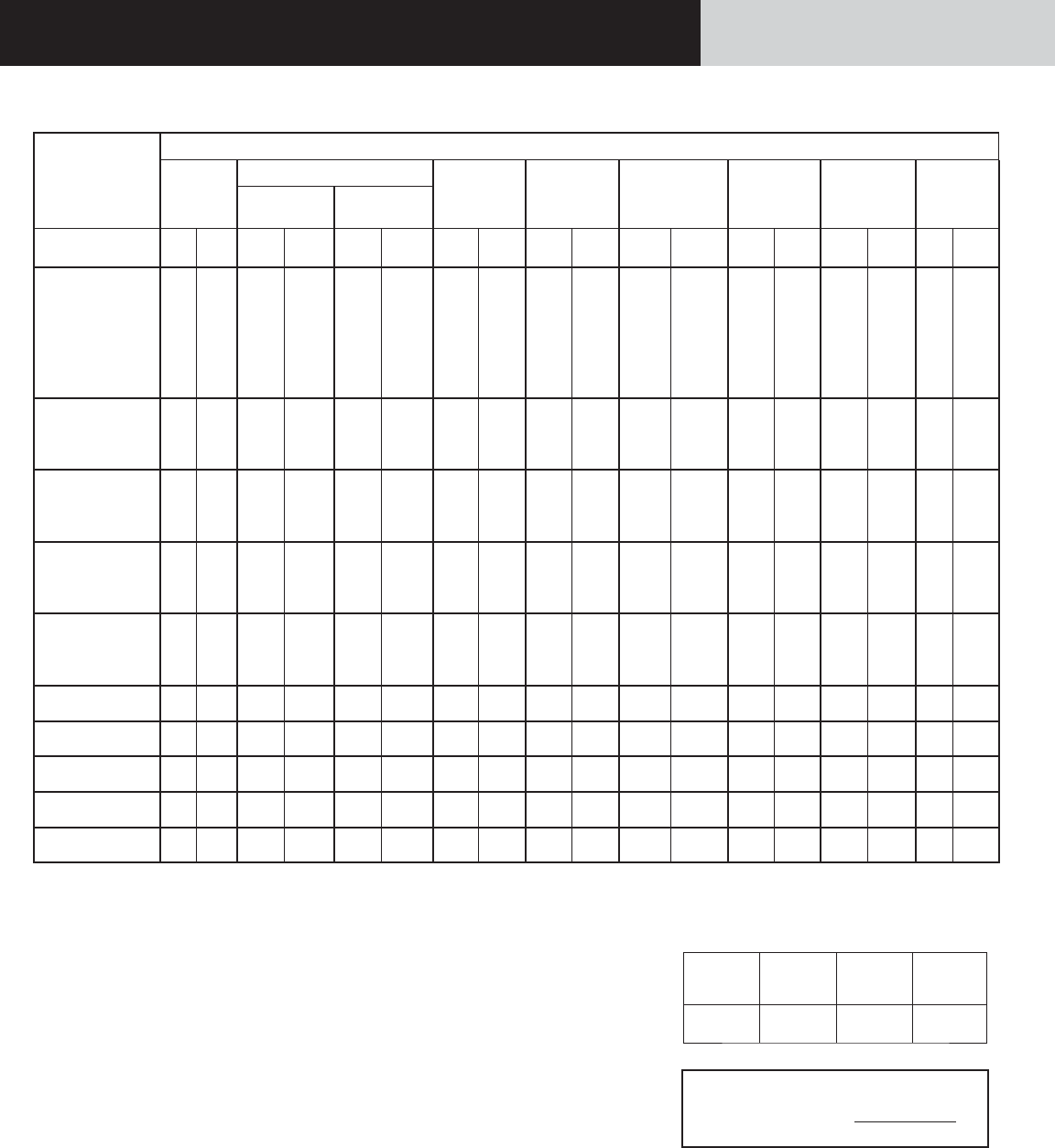

DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS

Table 3 – Specifi cations and Dimensions

Part Number*

Physical Characteristics (Nominal)

Weight

Mass

Inertia

A

Pilot O.D.

B

B.C. Dia.

C

Dia.

D

Dia.

E

Dia.

F

Length

Inner

Member

Outer

Member

Size

Variation lb kg

lb-in-

sec

2

kg-m

2

lb-in-

sec

2

kg-m

2

in mm in mm in mm in mm in mm in mm

LCD-0075

-XR-A

-XXR-A

6.5

8.3

2.95

3.76

0.04 0.004

0.21

0.35

0.024

0.039

8.500

12.375

215.90

314.33

7.875

11.625

200.03

295.28

2.875

73.03

3.375 85.73

No

Counter

Bore

No

Counter

Bore

2.62 66.55

LCD-0075

-XR-C

-XXR-C

6.5

8.3

2.95

3.87

0.04 0.004

0.21

0.35

0.024

0.039

8.500

12.375

215.90

314.33

7.875

11.625

200.03

295.28

2.875

73.03

3.375 85.73

No

Counter

Bore

No

Counter

Bore

2.62 66.55

LCD-0075

-X-C 6.3 2.87 0.04 0.004 0.07 0.007 10.340 262.58 9.625 244.48 2.813 71.45 3.313 84.14 2.688 68.28 2.00 50.8

LCD-0150 -XR-A

-XXR-A

20

13.8

9.07

6.26

0.13

0.08

0.015

0.009

0.29 0.033 12.375 314.33 11.625 295.28

2.875

2.500

73.03

63.50

3.375

3.400

85.73

86.36

4.25

4.57

107.95

120.65

2.80 71.12

LCD-0150 -XR-C

-XXR-C

20

13.8

9.07

6.26

0.13

0.08

0.015

0.009

0.29 0.033 12.375 314.33 11.625 295.28

2.875

2.500

73.03

63.50

3.375

3.400

85.73

86.36

4.25

4.57

107.95

120.65

2.80 71.12

LCD-0200 -XR-A

-XXR-A

21

16

9.52

7.26

0.22

0.09

0.025

0.010

0.69 0.078 13.875 352.42 13.125 333.38

4.000

2.500

101.60

63.50

4.625

3.400

117.47

86.36

5.50

5.33

139.70

135.38

2.80 71.12

LCD-0200 -XR-C

-XXR-C

21

16

9.52

7.26

0.22

0.09

0.025

0.010

0.69 0.078 13.875 352.42 13.125 333.38

4.000

2.500

101.60

63.50

4.625

3.400

117.47

86.36

5.50

5.33

139.70

135.38

2.80 71.12

LCD-0300 -XR-A

-XXR-A

33

18

14.96

8.16

0.59

0.25

0.067

0.028

0.92 0.104 13.875 352.42 13.125 333.38

4.000

4.000

101.60

101.60

4.625

5.125

117.47

130.18

6.00

6.69

152.40

170.00

3.06 77.72

LCD-0300 -XR-C

-XXR-C

33

18

14.96

8.16

0.59

0.25

0.067

0.028

0.92 0.104 13.875 352.42 13.125 333.38

4.000

4.000

101.60

101.60

4.625

5.125

117.47

130.18

6.00

6.69

152.40

170.00

3.06 77.72

LCD-0400 -X-A

-XX-A

45

48

20.41

21.77

0.57

0.93

0.065

0.150

2.83 0.320 13.875 352.42 13.125 333.38

6.000

4.000

152.40

101.60

7.000

4.625

177.80

117.47

8.00

6.00

203.20

152.4

2.75 69.85

LCD-0400 -X-C

-XX-C

45

48

20.41

21.77

0.57

0.93

0.065

0.150

2.83 0.320 13.875 352.42 13.125 333.38

6.000

4.000

152.40

101.60

7.000

4.625

177.80

117.47

8.00

6.00

203.20

152.4

2.75 69.85

LCD-0600 -X-A

-X-C

62 28.11 1.12 0.127 5.23 0.591 15.500 393.70 14.625 371.47

6.000

152.40

7.000 177.80 8.00 203.20 3.00 76.20

LCD-0800 -X-A

-X-C

81 36.60 1.25 0.141 8.21 0.928 17.000 431.80 16.250 412.75 7.500 190.50 8.500 215.90 9.50 241.30 3.50 88.90

LCD-1000 -X-A

-X-C

105 47.62 3.51 0.397 14.57 1.647 19.000 482.60 18.125 460.37 8.825 224.16 10.125 257.18 11.52 292.61 4.00 101.60

LCD-1500 -X-A

-X-C

160 72.58 6.23 0.704 32.50 3.673 22.500 622.22 21.375 542.93 10.000 254.00 11.500 292.10 13.25 336.55 4.25 107.95

LCD-2000 -X-A

-X-C

160 72.58 7.40 0.836 31.48 3.557 22.500 622.22 21.375 542.93 11.500 292.19 13.250 336.55 15.25 387.35 4.25 107.95

* Please consult LORD engineering for application review,

approval and availability.

Prolonged exposure to temperatures in the 0°F range and

below produces a signifi cantly reduced slip torque prior to

driveline warm-up. This condition may result in the coupling’s

inability to transmit adequate drive torque for applications

experiencing unusual cold temperature related parasitic

loading.

Blind assembly style with a notched periphery provides

trouble-free, sliding assembly on fl ywheel drive pins when

bolted access is not possible. Outer member is a composite

material.

Use Wood’s Sure-Grip

®

Bushing type SK or equivalent.

See detail drawings by part number for tolerances.

Pilot diameter tolerances are + .000/ -.005 in for -A Series

diameters and + .005/ -.000 in for -C Series diameters.

Tapered.

Refer to SAE J620c for fl ywheel numbers 6-1/2, 10, 11-1/2,

16; to SAE J927a for numbers 60, 80, 100, 120, 160. See

Tables 5 and 6.

Unless otherwise noted:

.xx dim ± 0.030 in (± 0.762 mm)

.xxx dim ± 0.015 in (± 0.381 mm)

It is advisable to refer to drawing of coupling before

ordering since it is not practical to show all details in this

catalog.

Defi nition of Part Numbering System

Part Type hp Rating

Attachment

Variation

Torsional

Stiffness

Variation

LCD -0400

-X

-XX

-A

Sure-Grip is a trademark of Altra Industrial Motion, Inc.

Torque Requirements:

Torque (lb-in) = 63025 x hp

rpm