9

Installation

Tools required for installation

wrench set (provided)

level

forklift or crane with straps

1. Remove the crate from around the planer

and any fasteners securing the planer to the

skid.

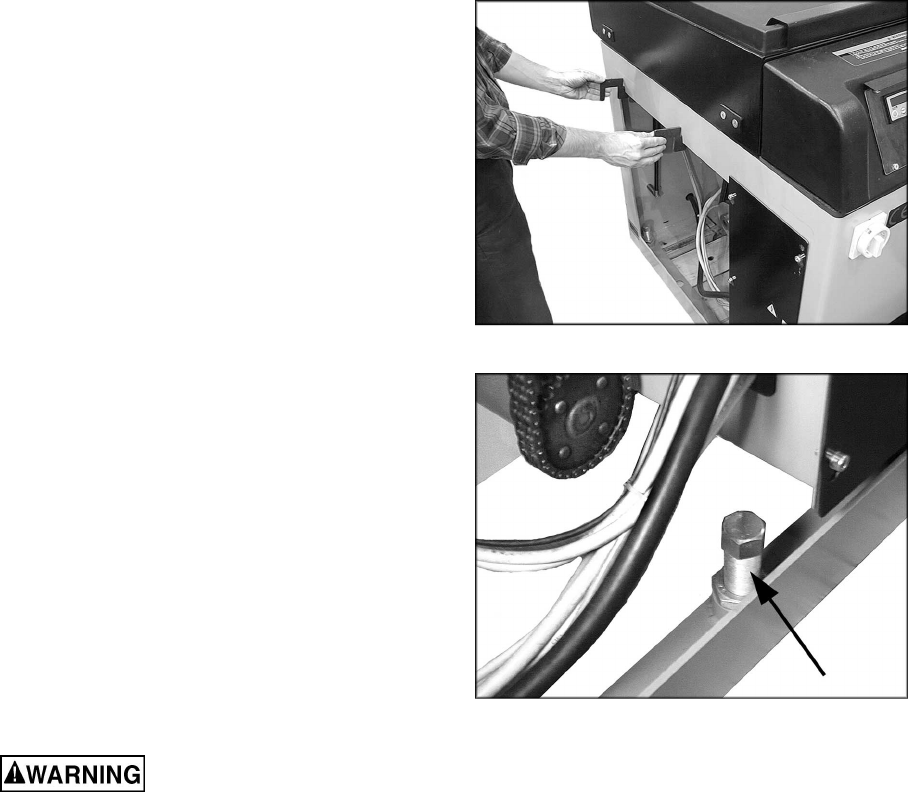

2. Remove the side covers and place the lifting

hooks into the slots (Figure 1). Place straps

under them and lift the machine off the skid.

The planer should be located on a sturdy

floor, preferably concrete, in a dry area with

sufficient lighting. Leave enough space

around the machine for loading and

offloading stock and routine maintenance

work.

3. When the planer is situated, use the leveling

screws (Figure 2) to level the machine.

4. Exposed metal areas of the planer have

been factory coated with a protectant. This

should be removed with a soft cloth and

kerosene. Do not use an abrasive pad. Do

not let solvent contact the plastic parts of

the machine, as it may damage them.

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. The

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The planer may be fitted with a 230 volt plug, or

may be “hard-wired” directly to your electrical

panel. If hard-wired to a panel, make sure a

disconnect is available for the operator.

IMPORTANT: The 230 volt model of the

WP2412 planer is wired for 230 volt only; it is

not convertible to 460 volt.

1. Make sure the machine’s plug is

disconnected from the power source. If it is

hard-wired, make sure the fuses have been

removed or the breakers have been tripped

in the circuit to which the saw will be

connected. Place a warning placard on the

fuse holder or circuit breaker to prevent it

being turned on while the machine is being

wired. Always follow proper Lock Out/Tag

Out procedures when performing any wiring

on this machine.

Figure 1

Figure 2