NOTE: Before installing welding wire,

be sure:

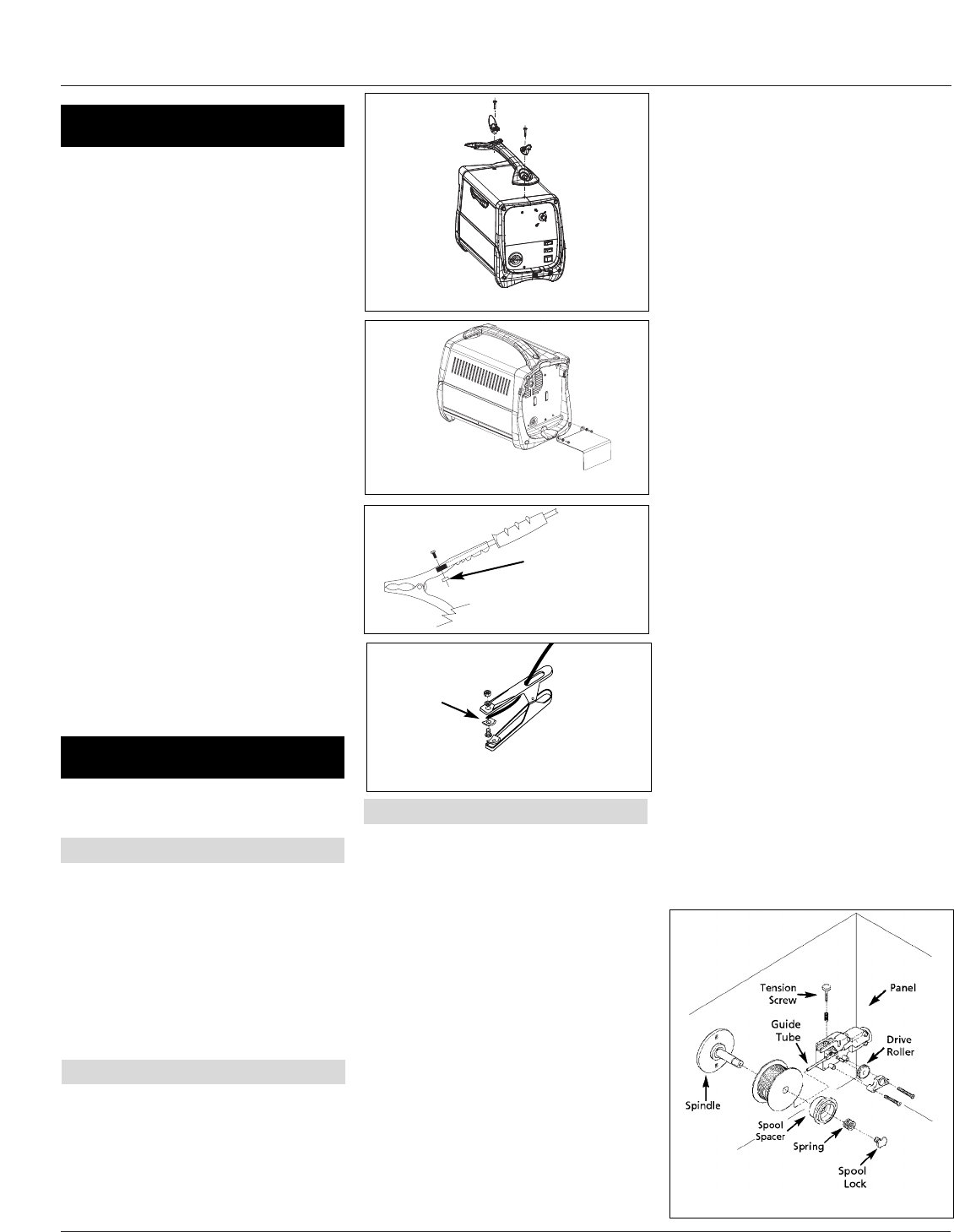

a. Diameter of welding wire matches

groove in drive roller on wire feed

mechanism (See Fig. 5). The drive

roller is marked with metric sizes:

.6mm = .024”, .8 - .9mm = .030 –

.035”

b. Wire matches contact tip in end of

gun. (See Fig. 6).

A mismatch on any item could cause the

wire to slip and bind.

NOTE: Always maintain control of loose

end of welding wire to prevent

unspooling.

1. Verify unit is off and open door

panel to expose wire feed

mechanism.

2. Remove the spool quick lock by

pushing in and rotating 1/4 turn

4

Wire Feed Arc Welder

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

● For best results locate welder in a

clean and dry environment. Dust

and dirt in the welder retain

moisture and increase wear of

moving parts.

● Place welder in an area with at least

twelve inches (305 mm) of ventilation

space at both the front and rear of

unit. Keep all obstructions out of this

ventilation space.

● Store welding wire in a clean, dry

location with low humidity to

prevent oxidation.

● Use a properly grounded receptacle

for the welder and ensure welder is

the only load on power supply

circuit. Refer to chart on page 1 for

correct circuit capacity.

● Use of an extension cord is not

recommended for electric arc welding

machines. Voltage drop in the

extension cord may significantly

degrade performance of the welder.

Welding accessories for the welder

are inside wire feed compartment.

1. Place handle assembly on welder,

aligning two holes in plastic ends

with threaded holes in welder

housing (Fig. 2).

2. Insert screws through cord wraps and

handle ends and fasten into cabinet.

3. Attach cylinder base to unit as shown

(Fig. 3).

1. Loosen hex bolt/nut on work clamp.

2. Insert cord (labeled ‘work clamp’ on

the front panel of the welder)

through clamp handle. Slide bare

wire under clamp block. Tighten hex

bolt/nut, making sure bare wire is

clamped securely (Figure 4).

counterclockwise. Then remove

knob, spring and spool spacer.

3. Loosen wire feed tensioning screw

on drive mechanism. This allows

initial feeding of wire into gun liner

by hand.

4. Install wire spool onto spindle so

wire can come off spool on the end

closest to the wire feed guide tube.

Do not cut the wire loose yet.

Install spool spacer, spring and quick

lock knob by pushing in and turning

knob 1/4 rotation clockwise.

5. Hold wire and cut the wire end from

spool. Do not allow wire to

unravel. Be sure end of wire is

straight and free of burrs.

6. Feed wire through wire feed guide

tube, over the groove in drive roll and

into gun liner. Snugly tighten wire feed

tensioning screw. Do not over tighten.

Three to four full turns is usually

correct.

7. Remove nozzle by turning counter-

clockwise, then unscrew contact tip

from end of welding torch (See

Figure 6). Plug welder into a proper

power supply receptacle.

8. Turn on welder and set wire speed

rate to 10. Activate gun trigger until

wire feeds out past the torch end.

Turn welder off.

9. Carefully slip contact tip over wire

and screw tip into torch end. Install

nozzle by turning clockwise (See

Figure 6). Cut wire off approximately

1/4 inch from nozzle end.

Figure 4a - Work Clamp

Assembly (WG2040,

WG2044, and WG2045)

Figure 3 - Base Assembly

Figure 2 - Handle Assembly

Assembly

Installation

HANDLE AND BASE ASSEMBLY

WORK CLAMP

WIRE INSTALLATION

www.chpower.com

Figure 5 - Weld Wire Routing

Clamping Block

Figure 4b - Work Clamp Assembly

(WG3000)

Clamping Block