8. Locate the clutch hub and armature assembly on the end

of the engine shaft. Note the two set screws as well as

the unused, threaded hole in the taper lock bushing at the

center of the clutch hub.

9. Using an 1/8” hex wrench, remove the two set screws

from the taper lock bushing

10. Thread one of the set screws into the unused, threaded hole

on the taper lock bushing. As the screw tightens, the bushing

will loosen. Once the bushing has loosened enough, slide the

clutch hub and armature assembly off the engine shaft.

11. Before replacing the clutch

hub and armature assembly

the proper “set back” must

be created. Using the

SprayTECH hub set-up tool

(P/N 0509925), create a “set

back” of 0.20” between the

friction surface of the clutch

armature and the forward face of the clutch hub.

12. Line up the three holes in the taper lock bushing with the

three holes in the clutch hub and insert the bushing into

the center of the clutch hub.

13. Line up the key on the taper lock bushing with the keyway

on the engine shaft and slide the assembly onto the shaft

with the holes facing out.

14. Apply blue Loctite to the

two set screws and insert

the screws into the taper

lock bushing. Tighten the

set screws only two turns

at this time.

15. Line up the forward face

of the clutch hub with the

front face of the clutch

housing. Using an 1/8”

hex wrench, alternately

tighten the set screws

into the taper lock bushing. Torque to 65–75 in/lbs.

16. Make sure the friction surface of the clutch armature is

clean and free from oil or grease.

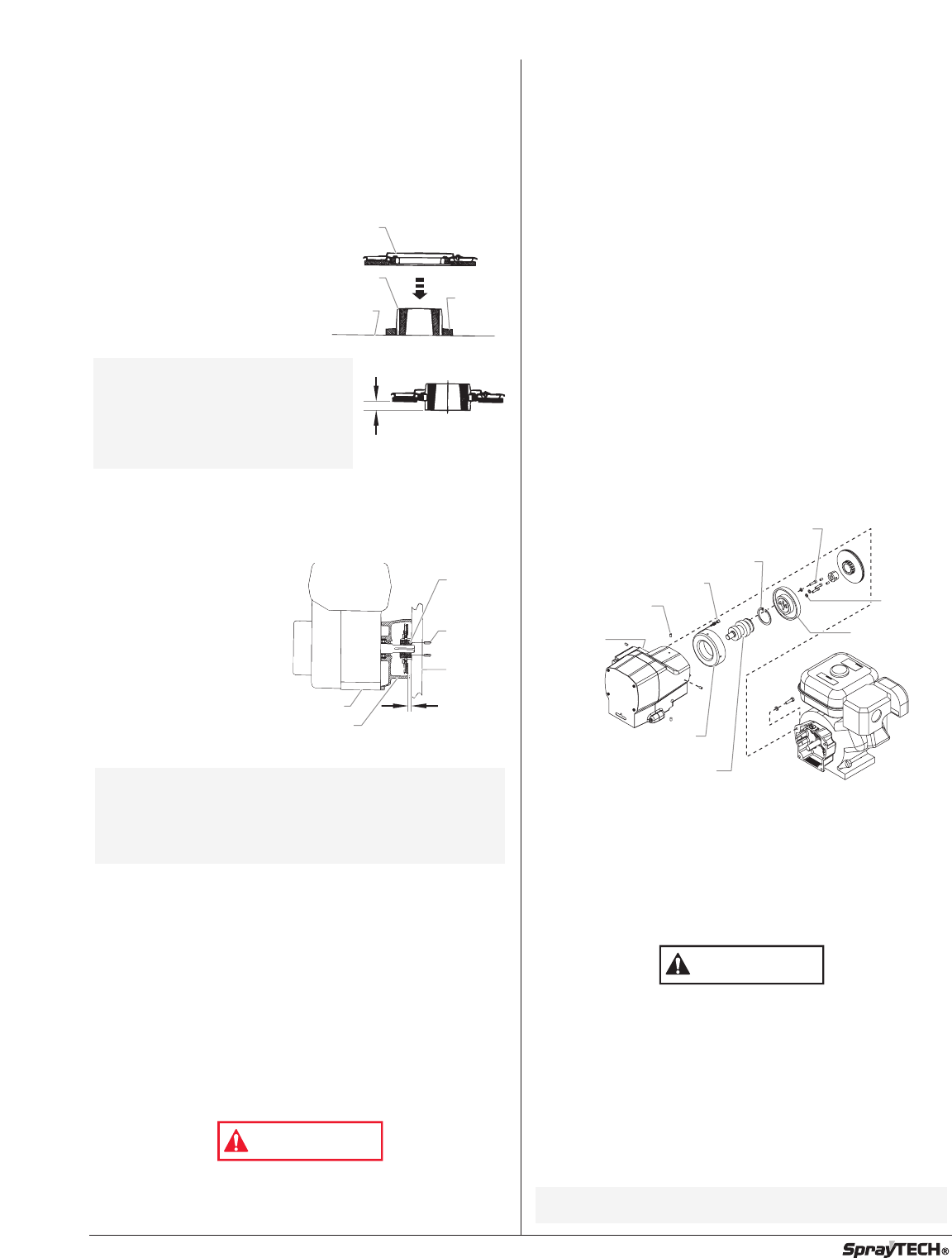

Removing the Clutch Rotor, Clutch Field, and

Drive Shaft Assembly

1. Follow steps 1–7 in “Removing/Replacing the Clutch Hub

and Armature Assembly.”

2. Locate the clutch rotor assembly on the end of the drive shaft

assembly. Note the locations of the three socket screws and

the two empty, threaded holes on the clutch rotor.

3. Using a 3/16” hex wrench, remove the three socket

screws and lock washers that secure the clutch rotor to

the drive shaft assembly.

4. Thread two of the socket screws into the empty, threaded

holes and tighten alternately. This will push the clutch

rotor away from the drive shaft assembly and pinion.

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

WARNING

NOTE: To ensure the clutch hub and the clutch

housing are aligned, hold a straight edge

across the face of the clutch housing and then

hold the clutch hub against the back of the

straight edge while tightening the two set

screws into the taper lock bushing.

Clutch

Housing

0.20"

Engine

Set

Screw

Straight

Edge

Taper

Lock

Bushing

NOTE: A new clutch hub and

armature assembly will

come pre-assembled, but

the “set back” will not be

correct. The “set back”

must still be created using

the hub set-up tool.

0.20"

Clutch

Hub

Flat

Surface

Set-Up

Tool

Clutch

Armature

5. Using a Phillips screwdriver, remove the four screws that

secure the EPC assembly to the EPC housing. Carefully

remove the EPC assembly from the housing.

6. Locate the two clutch field wires that pass from the gear

housing into the EPC housing through a grommet in the

back of the EPC housing. Remember the wire connection

terminals on the EPC assembly (label if necessary) and

disconnect the wires. Gently move the EPC assembly

away from the housing and rest it on the work surface by

the control housing.

7. Locate the four set screws that secure the clutch field to

the gear housing. They are located on the exterior of the

gear housing at the 12, 3, 6, and 9 o’clock positions while

facing the clutch field end of the gear housing. Using an

1/8” hex wrench, remove the setscrews. Remember the

location of the two clutch field wires with respect to the

grommet and EPC housing.

8. Carefully slide the clutch field out of the gear housing,

keeping the field square to the gear housing so it does not

bind.

9. Remove the retaining ring in front of the ball bearing

within the center bore of the gear housing.

10. Carefully slide the drive shaft assembly out from the gear

housing, keeping the shaft square to the housing so it

does not bind.

11. Remove the o-ring from inside the center bore of the gear

housing from which the small ball bearing on the drive

shaft assembly was removed.

12. Clean the inside of the gear housing.

Installing the Clutch Rotor Assembly, Clutch

Field and Drive Shaft Assembly

1. Install a new o-ring into the center bore of the gear housing.

2. Install the drive shaft assembly into the center bore of the

gear housing, keeping it square to the housing so it does

not bind. Once the large ball bearing on the drive shaft

assembly is half way into its bore, a soft hammer may be

used to gently tap the assembly into position.

Do not force the drive shaft assembly into position.

3. Install the retaining ring into its groove next to the large

ball bearing.

4. Line up the four holes around the outside of the clutch

field with the four set screw holes in the gear housing.

The clutch field wires should be at approximately the 1 or

2 o’clock position.

5. Route the two clutch field wires through the grommet and

into the EPC housing.

6. Carefully slide the clutch field into its bore in the gear

housing until it “bottoms out” within the housing. Do not

pinch the clutch field wires during installation.

NOTE: Apply blue Loctite to the four clutch field set

screws prior to installation.

CAUTION

Clutch Rotor

Socket Screw

Retaining Ring

Clutch Field Wires

Drive Shaft

Assembly

Clutch

Field

Clutch Field

Set Screw

EPC

Housing

Lock

Washer

Clutch

Rotor

© SprayTECH. All rights reserved. 13