*

VISCOELASTIC

Optional parameters when test data are given to define time domain viscoelasticity with

TIME=CREEP TEST DATA or TIME=RELAXATION TEST DATA or when test data are given to

define frequency domain viscoelasticity with FREQUENCY=PRONY, FREQUENCY=CREEP TEST

DATA, or FREQUENCY=RELAXATION TEST DATA:

ERRTOL

Set this param eter equal to the allowable average root-mean-square error of the data points in the

least-squares fit. The default is 0.01 (1%).

NMAX

Set this parameter equal to the maximum number of terms N in the Prony series. ABAQUS will

perform the least-squares fit from

to NMAX until convergence is achieved for the

lowest N with respect to ERRTOL. The default and maximum value is 13.

Data line to define continuum material properties for FREQUENCY=FORMULA:

First (and only) line:

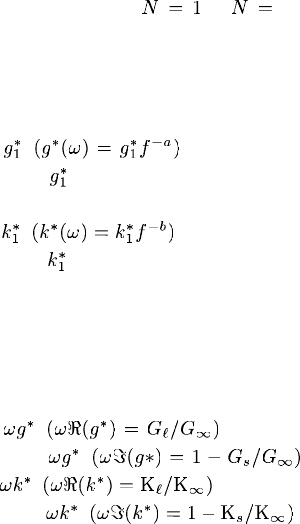

1. Real part of .

2. Imaginary part of .

3. Value of a.

4. Real part of

. If the material is incompres sible, this value is ignored.

5. Imaginary part of

. If the material is incompressible, this value is ignored.

6. Value of b. If the m aterial is incompressible, this value is ignored.

Data lines to define continuum material properties for FREQUENCY=TABULAR without the

PRELOAD parameter or for TIME=FREQUENCY DATA:

First line:

1. Real part of .

2. Imaginary part of .

3. Real pa rt of . If the material is incompressible, this value is ignored.

4. Imaginary part of

. If the material is incompressible, this va lue

is ignored.

5. Frequency, f, in cycles per time.

Repeat this data line as often as necessary to define the dissipative part of the material behavior.

Data lines to define continuum material properties for FREQUENCY=TABULAR,

PRELOAD=UNIAXIAL:

First line:

1. Uniaxial loss modulus.

2. Uniaxial storage modulus.

21.4–3

ABAQUS Version 6.1 Module:

ID:

Printed on: